Difference between revisions of "How to Make Grape Wine"

(→Grape Wine - Technical Brief) |

(→Packaging and storage) |

||

| Line 1: | Line 1: | ||

| − | |||

==Short Description== | ==Short Description== | ||

*'''Problem:''' | *'''Problem:''' | ||

| Line 85: | Line 84: | ||

Traditionally wine was delivered to the point of sale in casks. The product is traditionally packaged in glass bottles with corks, made from the bark of the cork oak (''Quercus suber''). The bottles should be kept out of direct sunlight. During storage, wines are prone to non-desirable microbial changes. Yeasts, lactic acid bacteria, acetic acid bacteria and fungi can all spoil or taint wines after the fermentation process is completed. | Traditionally wine was delivered to the point of sale in casks. The product is traditionally packaged in glass bottles with corks, made from the bark of the cork oak (''Quercus suber''). The bottles should be kept out of direct sunlight. During storage, wines are prone to non-desirable microbial changes. Yeasts, lactic acid bacteria, acetic acid bacteria and fungi can all spoil or taint wines after the fermentation process is completed. | ||

| − | </ | + | </hhhhhhhhhhhinnnnnnnnnnnnnnnnnu |

==White grape wine== | ==White grape wine== | ||

Revision as of 18:10, 6 May 2009

Contents

- 1 Short Description

- 2 Introduction

- 3 Red grape wine

- 4 Product description

- 5 Raw material preparation

- 6 Processing

- 7 Flow diagram

- 8 Packaging and storage

- 9 White grape wine

- 10 Product description

- 11 Raw material preparation

- 12 Processing

- 13 Flow diagram

- 14 Packaging and storage

- 15 References and further reading

- 16 Usefull addresses

- 17 Categories:

Short Description

- Problem:

- Idea:

- Difficulty:

- Price Range:

- Material Needeed:

- Geographic Area:

- Competencies:

- How Many people?

- How Long does it take?

Introduction

Grape wine is perhaps the most common fruit juice alcohol. Because of the commercialisation of the product for industry, the process has received most research attention.

The production of grape wine involves the following basic steps: crushing the grapes to extract the juice; alcoholic fermentation; maltolactic fermentation if desired; bulk storage and maturation of the wine in a cellar; clarification and packaging. Although the process is fairly simple, quality control demands that the fermentation is carried out under controlled conditions to ensure a high quality product.

Figure 1: Advice form ITDG Latin America helped improve the grapes and the yields of this wine producer in Peru. ©Ann Pilling/Practical Action

The distinctive flavour of grape wine originates from the grapes as raw material and subsequent processing operations. The grapes contribute trace elements of many volatile substances (mainly terpenes) which give the final product the distinctive fruity character. In addition, they contribute non-volatile compounds (tartaric and malic acids) which impact on flavour and tannins which give bitterness and astringency. The latter are more prominent in red wines as the tannin components are located in the grape skins.

Although yeasts are the principal organisms involved, filamentous fungi, lactic acid bacteria, acetic acid bacteria and other bacterial groups all play a role in the production of alcoholic fruit products. Normal grapes harbour a diverse micro-flora, of which the principal yeasts (Saccharomyces cerevisiae) involved in desirable fermentation are in the minority. Lactic acid bacteria and acetic acid bacteria are also present. The proportions of each and total numbers present are dependent upon a number of external environmental factors including the temperature, humidity, stage of maturity, damage at harvest and application of fungicides. It is essential to ensure proliferation of the desired species at the expense of the non-desired ones. This is achieved through ensuring fermentation conditions are such to encourage Saccharomyces species.

The fermentation may be initiated using a starter culture of Saccharomyces cerevisiae – in which case the juice is inoculated with populations of yeast of 106 to 107 cfu/ml juice (cfu refers to coliform forming units. It is a measure of the activity of micro-organisms). This approach produces a wine of generally expected taste and quality. If the fermentation is allowed to proceed naturally, utilising the yeasts present on the surface of the fruits, the end result is less controllable, but produces wines with a range of flavour characteristics. It is likely that natural fermentations are practised widely around the world, especially for home production of wine. In natural fermentations, there is a progressive pattern of yeast growth. Several species of yeast, including Kloeckera, Hanseniaspora, Candida and Metschnikowia, are active for the first two to three days of fermentation. The build up of end products (ethanol) is toxic to these yeasts and they die off, leaving Saccharomyces cerevisiae to continue the fermentation to the end. S. cerevisiae can tolerate much higher levels of ethanol (up to 15% v/v or more) than the other species who only tolerate up to 5 or 8% alcohol.

Because of its tolerance of alcohol, S. cerevisiae dominates wine fermentation and is the species that has been commercialised for starter cultures.

Red grape wine

Red grape wines are made in many African, Asian and Latin American countries including Algeria, Morocco and South Africa.

Product description

Red grape wine is an alcoholic fruit drink of between 10 and 14% alcoholic strength. The colour ranges from a light red to a deep dark red. It is made from the fruit of the grape plant (Vitis vinifera).

There are many varieties of grape used including Cabernet Sauvignon, Grenache, Nebbiolo, Pinot Noir, and Torrontes. The skins of the grape are allowed to be fermented in red wine production, to allow for the extraction of colour and tannins, which contribute to the flavour.

Raw material preparation

Ripe and undamaged grapes should be used. Red grapes are crushed to yield the juice plus skins, which is known as must.

Processing

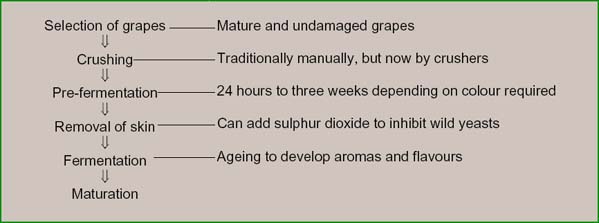

The crushed grapes are transferred to fermentation vessels. The ethanol formed during this fermentation assists with the extraction of pigments from the skins. This takes between 24 hours and three weeks depending on the colour of the final product required.

The skins are then removed and the partially fermented wine is transferred to a separate tank to complete the fermentation. The fermentation can be from naturally occurring yeasts on the skin of the grape or using a starter culture of Saccharomyces cerevisiae – in which case the juice is inoculated with populations of yeast.

Traditionally, fermentation was carried out in large wooden barrels or concrete tanks. Modern wineries now use stainless steel tanks as these are more hygienic and provide better temperature control.

Fermentation stops naturally when all the fermentable sugars have been converted to alcohol or when the alcoholic strength reaches the limit of tolerance of the strain of yeast involved. Fermentation can be stopped artificially by adding alcohol, by sterile filtration or centrifugation.

Some wines can be drunk immediately. However most wines develop distinctive favours and aromas by ageing in wooden casks.

Flow diagram

Packaging and storage

Traditionally wine was delivered to the point of sale in casks. The product is traditionally packaged in glass bottles with corks, made from the bark of the cork oak (Quercus suber). The bottles should be kept out of direct sunlight. During storage, wines are prone to non-desirable microbial changes. Yeasts, lactic acid bacteria, acetic acid bacteria and fungi can all spoil or taint wines after the fermentation process is completed.

</hhhhhhhhhhhinnnnnnnnnnnnnnnnnu

White grape wine

White grape wines are made in many African, Asian and Latin American countries including Algeria, Morocco and South Africa.

Product description

White grape wine is an alcoholic fruit drink of between 10 and 14% alcoholic strength. The colour is a pale yellow. It is made from the fruit of the grape plant (Vitis vinifera).

There are many varieties used including Airen, Chardonnay, Palomino, Sauvignon Blanc and Ugni Blanc. The main difference between red and white wines is the early removal of grape skins in white wine production.

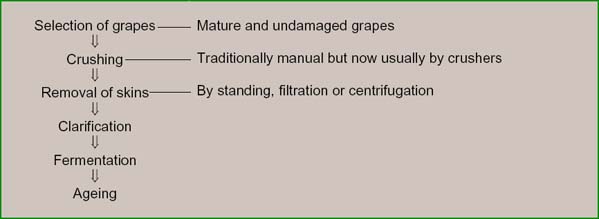

Raw material preparation

Ripe and undamaged grapes should be used. The grapes are crushed to yield the juice and the skins are removed and separated out. Sometimes the juice is clarified by allowing it to stand for 24 to 48 hours at 5 to 10° C, by filtering or centrifugation. Pectolytic enzymes may be added to accelerate the breakdown of cell wall tissue and to improve the clarity of juice. Excessive clarification removes many of the natural yeasts and flora. This is beneficial if a tightly controlled induced fermentation is desired, but less so if the fermentation is a natural one. Long periods of settling out however, encourage the growth of natural flora, which can contribute to the fermentation.

Processing

The clarified juice is transferred to a fermentation tank where fermentation either begins spontaneously or it is induced by the addition of a started culture. Traditionally, fermentation was carried out in large wooden barrels or concrete tanks. Modern wineries now use stainless steel tanks as these are more hygienic and provide better temperature control. White wines are fermented at 10 to 18º C for about seven to fourteen days. The low temperature and slow fermentation favours the retention of volatile compounds. The fermentation can be from naturally occurring yeasts on the skin of the grape or using a starter culture of Saccharomyces cerevisiae.

During storage, wines are prone to non-desirable microbial changes. Yeasts, lactic acid bacteria, acetic acid bacteria and fungi can all spoil or taint wines after the fermentation process is completed.

Flow diagram

Packaging and storage

Traditionally wine was delivered to the point of sale in casks. The product is traditionally packaged in glass bottles with corks, made from the bark of the cork oak (Quercus suber). The bottles should be kept out of direct sunlight. During storage, wines are prone to non-desirable microbial changes. Yeasts, lactic acid bacteria, acetic acid bacteria and fungi can all spoil or taint wines after the fermentation process is completed.

References and further reading

This Howtopedia entry was derived from the Practical Action Technical Brief Grape Wine.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_food_processing

• Small-scale Food Processing: A guide to appropriate equipment, P. Fellows, A Hampton, IT Publications/CTA

• Elaboración de Vino: Proyecto San Martín, A. Puerta, ITDG-Perú/CEPCO, 2000 (In Spanish)

• Vino de Frutas: serie procesamiento de alimentos 6, ITDG-Perú, 1998 (In Spanish)

• Toddy & Palm Wine, M. Battcock, Practical Action Technical Brief, 1998.

• Banana Beer, M. Battcock, Practical Action Technical Brief, 1998.

Usefull addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail:practicalaction@practicalaction.org.uk web:www.practicalaction.org