Difference between revisions of "How to Preserve Food by Drying"

(→Categories) |

(→References and further reading) |

||

| Line 426: | Line 426: | ||

<div class="booktext"> | <div class="booktext"> | ||

| − | '''This Howtopedia entry was derived from the Practical Action Technical Brief ''Processing of | + | '''This Howtopedia entry was derived from the Practical Action Technical Brief ''Processing of Pepper''. <br />To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_food_processing'''<br /> |

''Anagi Tray Dryer'', Practical Action Technical Brief | ''Anagi Tray Dryer'', Practical Action Technical Brief | ||

Latest revision as of 13:58, 11 March 2010

Contents

Drying of Foods - Technical Brief

Drying of Foods

Drying is used to remove water from foods for two reasons: to prevent (or inhibit) microorganisms and hence preserve the food and to reduce the weight and bulk of food for cheaper transport and storage.

When carried out correctly, the nutritional quality, colour, flavour and texture of rehydrated foods are slightly less than fresh food but, for most people, this has only minor nutritional significance as dried foods form one component in the diet.

However, if drying is carried out incorrectly there is a greater loss of nutritional and eating qualities and more seriously, a risk of microbial spoilage and possibly even food poisoning.

This technical brief therefore describes some of the requirements for proper drying and summarises information on the various drying equipment available.

Drying can be carried out using hot air or, less commonly, hot metal pans. The last stage in making gari is an example of drying using hot metal but in this technical brief, we shall concentrate on drying using hot air.

For effective drying, air should be hot, dry and moving. These factors are inter-related and it is important that each factor is correct (for example, cold moving air or hot, wet moving air is unsatisfactory). The dryness of air is termed 'humidity' - the lower the humidity, the drier the air. There are two ways of expressing humidity (or RH) the most useful is a ratio of the water vapour in air to air which is fully saturated with water. So 0% RH is completely dry air and 100% RH is air that is fully saturated with water vapour.

Low RH (or dry) air must be blown over foods so that it has the capacity to pick up water vapour from the food and remove it. If high RH (or wet) air is used it quickly becomes saturated and can not pick up further water vapour from the food.

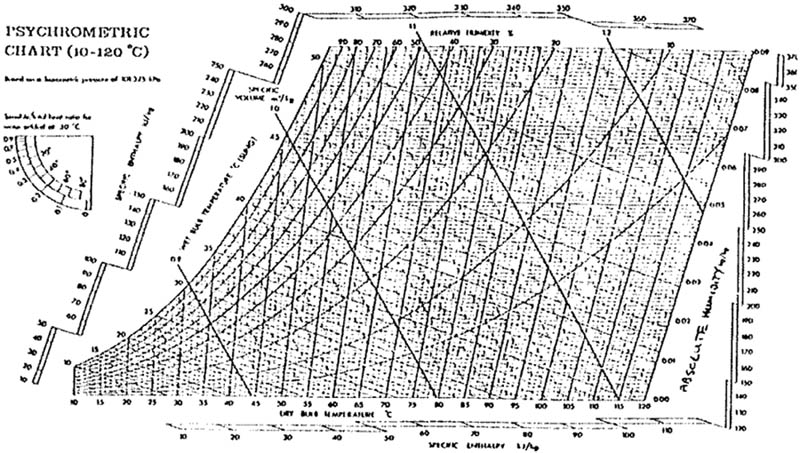

The temperature of the air affects the humidity (higher temperatures reduce the humidity and allow the air to carry more water vapour). The relationship between temperature and RH is conveniently shown on a psychrometric chart, Figure 1.

Note that there are two types of air temperature:

The temperature of the air, measured by a thermometer bulb, is termed the dry-bulb temperature. If the thermometer bulb is surrounded by a wet cloth, heat is removed by evaporation of the water from the cloth and the temperature falls (to the 'wet bulb' temperature). The difference between the two temperatures is used to find the relative humidity of air of the psychrometric chart.

The dew point is the temperature at which air becomes saturated with moisture (100% RH) and any further cooling from this point results in condensation of the water from the air. This is seen at night when air cools and water vapour forms as dew on the ground. Adiabatic cooling lines are the parallel straight lines sloping across the chart, which show how absolute humidity decreases as the air temperature increases.

The psychrometric chart is useful for finding changes to air during drying and hence the efficiency of a drier. The following examples show how it is used.

Using Figure 1, find:

1 the absolute humidity of air which has 50% RH and a dry-bulb temperature of 60°C

2 the wet-bulb temperature under these conditions

3 the RH of air having a wet-bulb temperature of 45°C and a dry-bulb temperature of 75°C

4 the dew point of air cooled adiabatically from a dry-bulb temperature of 55°C and 30% RH

5 the change in RH of air with a wet-bulb temperature of 39°C, heated from a dry-bulb temperature of 50°C to a dry-bulb temperature of 86°C

6 the change in RH of air with a wet-bulb temperature of 35°C, cooled adiabatically from a dry-bulb temperature of 70°C to 40°C.

Answers

1 0.068kg per kilogram of dry air (find the intersection of the 60°C and 50% RH lines, and then follow the chart horizontally right to read off the absolute humidity)

2 246.5°C (from the intersection of the 60°C and 50% RH lines, move left parallel to the wet-bulb lines to read off the wet-bulb temperature)

3 20% (find the intersection of the 45°C and 75°C lines and follow the sloping RH line upwards to read off the % RH)

4 36°C (find the intersection of the 55°C and 30% RH lines and follow the wet-bulb line left until the RH reaches 100%)

5 50-10% (find the intersection of the 39°C wet-bulb and the 50°C dry-bulb temperatures, and follow the horizontal line to the intersection with the 86°C dry-bulb line; read the sloping RH line at each intersection (this represents the changes that take place when air is heated prior to being blown over food))

6 10-70% find the intersection of the 35°C wet-bulb and 70°C dry-bulb temperature, and follow the wet-bulb line left until the intersection with the 40°C dry-bulb line; read sloping RH line at each intersection (this represents the changes taking place as the air is used to dry food; the air is cooled and becomes more humid as it picks up moisture from the food). If a new type of drier is to be used, or if a different type of food is to be dried, it is necessary to do some experiments to find the rate of drying. The information can then be used to find the time that the food should spend in the drier before the moisture content is low enough to prevent spoilage by micro-organisms. The rate of drying also has an important effect on the quality of the dried foods and (in artificial driers) the fuel consumption. To find the rate of drying you will need a clock/watch and a set of scales. Food is weighed, placed in the drier and left for 5 -10 minutes. It is then removed, reweighed and replaced. This is continued until the weight of the food no longer changes. The interval between weighings can be increased when the changes in weight start to become less. You should also make a note of the wet and dry bulb temperatures of the air inside the drier and the air outside. The results are plotted on a graph, Figure 2 and show two distinct phases of drying - the 'constant' and ‘falling’ rate periods. In the constant rate the surface of the food remains wet and it can therefore be spoiled by moulds and bacteria. In the falling rate the surface is dry and the risk of spoilage is much smaller. The food should therefore be dried to a weight that corresponds to the end of the constant rate period as quickly as possible (however see 'case hardening' below)

<center>

The information from an experiment can be more usefully shown as in Figure 3, by calculating drying rate for each 10 minute period as follows:

The moisture content of both the fresh food and the final dried food can be found by weighing the food, heating at 100°C in an oven for 24 hours and reweighing. The moisture content is found as follows:

Other values of moisture content during the drying period can be found by relating these two results to the weights of food recorded during the drying experiment and applying similar factors to intermediate weights. Figure 3 gives two important pieces of information:

1 The actual drying rate during the constant rate period which shows how efficient the drier is

2 The final moisture content of the dried food which shows whether it will be stable during storage

Typically, a drying rate of 0.25kg/hr would be expected for solar driers depending on the design and climate, and 10-15kg/hr for artificial driers. To ensure safe storage the final moisture content of the food should be less than 20% for fruits and meat, less than 10% for vegetables and 10-15% for grains.

If the drying rate is lower than this, the air temperature or speed is too low and/or the RH is too high. This can be checked by the temperature measurements made during the experiment and by using the psychrometric chart. Normally the air in the drier should be 10-15ºC above room temperature in solar driers and 60-70ºC in artificial driers. The RH of air entering the drier will vary according to local conditions, but should ideally be below about 60% RH.

The stability of a dried food during storage depends on its moisture content and the ease with which the food can pick up moisture from the air. Clearly the risk of moisture pick up is greater in regions of high humidity. However, different foods pick up moisture to different extents (compare for example the effect of high humidity on salt or sugar with the effect on pepper powder -salt and sugar pick up moisture, pepper doesn't).

For foods that readily pick up moisture it is necessary to package them in a moisture proof material.

A low moisture content is only an indication of food stability and not a guarantee. It is the availability of moisture for microbial growth that is more important and the term 'Water Activity' (AW) is used to describe this. Water Activity varies from 0-1.00 and the lower the value the more difficult it is for micro-organisms to grow on a food.

Examples of moisture contents and AW values for selected foods and their packaging requirements are shown in Table 1.

|

Food |

Moisture content % |

Water activity |

Degree of protection required |

|

Fresh meat |

70 |

0.985 |

Package to prevent moisture loss |

|

Bread |

40 |

0.96 |

. |

|

Marmalade |

35 |

0.86 |

. |

|

Rices |

15-17 |

0.80 |

Minimum protection or no packaging required |

|

Wheat flour |

14.5 |

0.72 |

. |

|

Raisins |

27 |

0.60 |

. |

|

Macaroni |

10 |

0.45 |

. |

|

Marzipan |

15-17 |

0.75 |

. |

|

Oats |

10 |

0.65 |

. |

|

Nuts |

18 |

0.65 |

. |

|

Toffee |

8 |

0.60 |

Packaged to prevent moisture dried uptake |

|

Cocoa powder |

0.40 |

. |

. |

|

Boiled sweets |

3.0 |

0.30 |

. |

|

Biscuits |

5.0 |

0.20 |

. |

|

Milk |

3.5 |

0.11 |

. |

|

Potato crisps |

1.5 |

0.08 |

. |

|

Spices |

5-8 |

0.50 |

. |

|

Dried vegetables |

5 |

0.20 |

. |

|

Breakfast cereal |

5 |

0.20 |

. |

Table 1: Food Type characteristics and packaging requirements

Case hardening and other effects of drying

Case hardening is the formation of a hard skin on the surface of fruits, fish and some other foods which slows the rate of drying and may allow mould growth. It is caused by drying too quickly during the initial (constant rate) period and can be prevented by using cooler drying air.

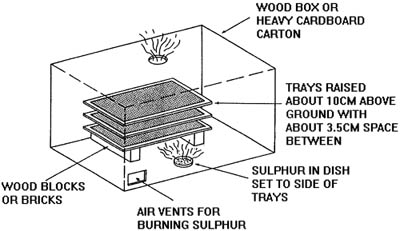

Other changes to foods include colour loss, flavour loss and hardening. Experiments with air temperature and speed can be used to select the best conditions for each food. The colour of many fruits can be preserved by dipping in a solution of 0.2-0.5% sodium metabisulphite or by exposing to sulphur dioxide in a sulphuring cabinet, Figure 4.

Vitamin losses are often greater during peeling/slicing etc than during drying. Loss of fat soluble vitamins can be reduced by shade drying and loss of water soluble vitamins by careful slicing using sharp knives. Blanching of vegetables is necessary before drying and water soluble vitamins are also lost in this stage. It should be noted that drying does not destroy micro-organisms and only inhibits their growth.

So heavily contaminated fresh foods will become heavily contaminated dried and rehydrated foods. Blanching is one method of reducing the levels of initial contamination. Thorough washing of fresh foods should be done routinely before drying.

Summary of small-scale drying equipment available

Solar driers

Solar drying is popular with agencies and research stations. However, there are no small-scale solar driers that are yet operating economically. There are a number of reasons for this:

- The amount of food lost in traditional drying is often over estimated (people report the worst case and the average amount)

- The loss of quality is not necessarily reflected in lower prices. People are willing to pay nearly the same amount for discoloured or damaged foods and there is therefore no incentive for producers to risk higher amounts of money in a drier when there is not a great return

- Different quality standards are applied by agencies and rural people. It is not necessary to achieve export quality for sale in rural areas

- Driers are only needed in villages if the weather is unsuitable for traditional methods. If these conditions are not very common, the drier will not be needed. Even short periods of sunshine are enough to prevent serious crop losses. Some producers wait for sunshine rather than risk the expense of using a drier. The food is then either spoiled or the drier is not big enough to handle the amounts involved

- Other methods are available to preserve the food if it rains during harvest, for example the harvest can be delayed, food can be stacked in a way which prevents it from getting wet, or small amounts can be dried over a kitchen fire, or mixed with dry crop

- Some benefits of proper drying (for example absence of mould, and better milling characteristics of grains) cannot be seen and there is therefore no increase in value of the food

Other disadvantages of both solar and mechanical driers include greater space and labour requirements than traditional methods (for example loading, unloading of trays). These costs are given lower value by agencies than by villagers.

Solar driers operate by raising the temperature of the air to between 10-30ºC above room temperature. This makes the air move through the drier and also reduces its humidity.

There are advantages to solar drying as follows:

The higher temperature, movement of the air and lower humidity, increases the rate of drying. Food is enclosed in the drier and therefore protected from dust, insects, birds and animals. The higher temperature deters insects and the faster drying rate reduces the risk of spoilage by micro-organisms. The higher drying rate also gives a higher throughput of food and hence a smaller drying area. The driers are water proof and the food does not therefore need to be moved when it rains. Driers can be constructed from locally available materials and are relatively low cost.

Designs vary from very simple direct driers (for example a box covered with plastic to trap the sun's heat) to more complex indirect designs which have separate collectors and drying chambers. The most common type of collector is a bare galvanised iron plate which is painted matt black. These give a temperature increase of 10ºC and increases the air speed to about 5m/s. Other types include burnt rice husks or charcoal.

The collectors are covered with a transparent material to ensure uniform airflow. Glass covers are best but they break easily, are heavy and expensive. Plastic often has poor stability to sunlight and weather, but is about 10% of the weight of glass and does not break. The best types of plastic are polyester and polycarbonate when available. Polythene is cheaper and more widely available but is not as strong and is less resistant to damage by light and weather.

The food can be either exposed to the sunlight (in direct systems) or heated air is passed over shaded food in indirect systems. Direct systems are used for food such as raisins, grains and coffee where the colour change caused by the sun is acceptable, but most foods need indirect systems to protect the colours in the food. Other types of driers use fans to blow the air over the food but this adds to the capital and operating cost and removes the advantages of driers in rural areas which can not operate without electricity.

There are three basic types of drier, each of which has many variations. 1, tent driers (direct), 2, cabinet driers (direct or indirect) and 3, chimney driers (indirect). Each of these types uses natural air circulation although it is possible to fit an electric or wind powered fan to increase the speed of the air.

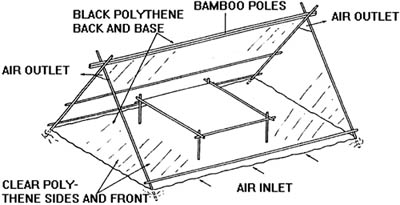

Tent drier - Figure 5

This type consists of a ridge tent framework, covered in clear plastic on the ends and the side facing the sun, and black plastic on the base and the side in shade. A drying rack is placed along the full length of the tent. The bottom edge of the clear plastic is rolled around a pole, which can be raised or lowered to control the flow of air into the drier. Moist air leaves through holes in the top corners of the tent.

The advantages of this type of drier are the low construction costs and simplicity of operation. However, like other types of solar drier, there is relatively poor control over the RH of the air in the drier and so, poor control over drying rates. It is also lightweight and fairly fragile when moved or in windy conditions.

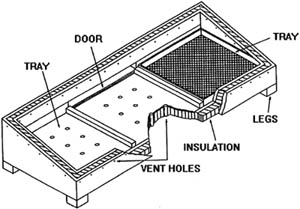

Cabinet drier - Figure 6

The basic design is an insulated rectangular box, covered with clear glass or plastic. There are holes in the base and upper parts of the box to allow fresh air to enter and moist air to leave. The inside of the cabinet is painted black to act as a solar collector. In indirect types, a flat plate is painted black and suspended in a insulated frame. Air is heated on both sides of the plate before passing into the drying cabinet. Food is placed on perforated trays within the cabinet and warm air from the collector rises up through the food and leaves through the top. The length of the cabinet is approximately three times the width to prevent shading by the sidewalls.

The sides can be made from board or mud-coated basket work. Larger models can be made from mud, brick or cement. The insulation can be wood shavings, sawdust, coconut fibre, dried grass or leaves, but should be at least 5cm thick to keep the inside temperature high. If insects are a problem, the air holes should be covered with mosquito netting. Drying trays should be made from basket work or plastic mesh. Metal should not be used as it can react with the acids in fruits and some vegetables and cause off-flavours in the food. These type of driers are used for fish, fruit, vegetables, root crops and oilseeds. They have capacities of up to 1 tonne.

Chimney drier

This is a modified cabinet drier in which a solar collector of black plastic or burnt husks is covered by clear plastic on a wooden framework. A black plastic chimney heats up the air above the exit to the drier and therefore increases the airflow through the drier.

Artificial (mechanical) drier

These use fuel to increase the air temperature, and reduce the RH and fans to increase air speed. They give close control over the drying conditions and hence produce high quality products. They operate independently of the weather and have low labour costs. However, they are more expensive to buy and operate than other types of driers. In some applications, where consistent product quality is essential, it is necessary to use mechanical driers.

Light bulb drier

This consists of an electric light bulb inside a wooden box. If electricity is available this is a simple, low cost drier which may be suitable for home preservation. The capacity is very small and it is not likely to be useful for income generation. The bottom of a box is painted black, or covered in soot or black cloth. The sides are covered in shiny material (for example aluminium paint) to reflect the heat onto the black surface. Air circulates by natural convection in a similar way to the solar cabinet drier, but in this case the drier can operate all night as well as all day.

Cabinet drier

The design is similar to the solar type but in this case the heat is supplied by burning fuel or electricity. If electricity is available, a fan can be used to increase the speed of air moving over the food and therefore increase the rate of drying. To be economical it is likely that this type of drier should be relatively large (1-5 tonnes). These are successfully used for drying herbs, tea and vegetables.

Practical Action has developed a range of drying systems including a small, low-cost industrial type which can be fabricated in countries of intended use. Its small size makes it suitable for decentralised use in crop-growing areas. The price at about US$ 3,000, is substantially lower than for standard, commercially available units.

The small unit is a semi-continuous drying cabinet with hot air supplied by an indirect heater-blower unit. Intended for round-the-clock operation, the semi-continuous tray drier is designed for maximum fuel efficiency. It takes about four hours for the first (bottom) tray to dry: after that, it can be removed, the remaining trays lowered, leaving a space at the top for a tray of fresh material. Trays can then be removed every twenty minutes.

Silo dryer

These driers consist of trays or tanks containing a deeper layer of food than those found in cabinet driers.

They have a larger capacity and are often used for grain drying, where the amount of water to be removed is smaller than for example fruits and vegetables, but the quantities involved are larger.

There is considerable scope for the use of small driers that combine the low cost of solar heating with better control of mechanical driers.

References and further reading

This Howtopedia entry was derived from the Practical Action Technical Brief Processing of Pepper.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_food_processing

Anagi Tray Dryer, Practical Action Technical Brief

Drying of Apricots, Practical Action Technical Brief

Drying of Chillies, Practical Action Technical Brief

Drying Technologies, Practical Action Technical Brief

Solar Drying, Practical Action Technical Brief

Tray Dryers, Practical Action Technical Brief

Drying Food for Profit: A Guide for Small Businesses, Barrie Axtell, ITDG Publishing, 2002

Drying Foodstuffs: Techniques, Processes, Equipment, Jean-François Rozis, Backhuys Publishers, 1997

Producing Solar Dried Fruit and Vegetables for Micro-and Small-scale Rural Enterprise Development: A Series of Practical guides, Natural Resource Institute, 1996

Related Articles

- How to Preserve Food with Small Scale Drying Technologies

- How to Preserve Food by Drying

- How to Use Sun Power

- How to Make Chocolate

- How to Preserve Tomato

- How to Preserve Food with a Solar Dryer

- How to Process Spice

- How to Process Turmeric

- How to Build a Tray Dryer

- The Anagi Tray Dryer

- How to Dry Chillies

- How to Process Pepper

Usefull addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail: practicalaction@practicalaction.org.uk

web: www.practicalaction.org