Difference between revisions of "How to Make Lime Oil and Juice"

(→Categories) |

|||

| Line 204: | Line 204: | ||

[[Category:More than 5 People]] [[Category:Food Processing]] [[Category:Small Industry]] [[Category:Products]] [[Category:Application]] [[Category:Oil]] | [[Category:More than 5 People]] [[Category:Food Processing]] [[Category:Small Industry]] [[Category:Products]] [[Category:Application]] [[Category:Oil]] | ||

[[Category:Howtopedia requested drawings]] [[Category:Howtopedia requested images]] | [[Category:Howtopedia requested drawings]] [[Category:Howtopedia requested images]] | ||

| − | [[Category:Requested translation to Spanish | + | [[Category:Requested translation to Spanish]] |

| − | + | [[fr:Comment faire de l'huile et du jus de lime]] | |

Latest revision as of 08:21, 26 May 2010

Contents

Introduction

The production of oil and juice on a commercial scale requires the use of a range of equipment for washing the fruit, crushing, screening raw juice from course pulp and seeds and setting vats for distilled oil production. Before considering the equipment in detail, the requirements for lime fruit processing should be first assessed on the throughput of the crushing unit relevant to the quantities of fruit to be handled.

Harvesting

It is generally accepted that the best compromise, from the point of view of both quality and quantity of lime products, is obtained by processing mature but not fully ripe fruit, ie half yellow/half green limes. Juice from unripe limes is said to have a more 'interesting' flavour than juice obtained from fully ripe limes. The distilled oil from unripe fruit is also said to be superior in quality.

Preparation for processing

Only sound fruit should be crushed; over-ripe, rotten and damaged limes should be removed before washing.

Limes should be thoroughly washed with cold water before processing so that they are perfectly clean when entering the crusher. This is particularly important when limes have been picked-up from the ground as they may be very muddy in the rainy season and all mud must be removed.

Rotary cage-type washers work very well, also water jets can be sprayed on conveyor belts along which the limes travel from the arrival point to the crushers.

Another conveyor belt, for final inspection, is needed to remove any damaged, fruit and to transport the limes to the crusher.

The two main types of equipment employed for crushing limes are the roller-crusher or a screw press expeller. Both methods have their advantages and disadvantages:

Roller-crusher

Triple granite rollers crush the limes and press out juice and oil. As a result there is not a great deal of fine pulp present in the raw juice and the product tends to settle fairly rapidly, settling often being complete within 2 or 3 weeks. Rollers need relatively little adjustment, but cannot extract at as high a rate as the screw press.

The throughput of limes is 1½-2 tons an hour, when using rollers 30" long and 10" in diameter, but the actual throughput depends to a large extent on the efficiency of feeding the fruit to the rollers. This size of machine should deal with about 100 tons of limes a week. The roller mill is considered to give a good quality settled juice, with separation from top pulp/oil after about 2 weeks storage in vats.

Screw-press

Screw-presses are generally made of stainless steel or bronze and do more 'work' on the limes than roller-crushers. The skins emerge from the screw-press in a shredded state. As a result the raw juice contains more fine pulp, after sieving, than juice from a roller mill and therefore takes longer to settle. Also, the settled juice from a screw-press is rarely as clear as that obtained from a roller mill. However, this need not be a drawback if a filter press is used to clarify the settled juice. Higher yields of raw juice are obtainable from the screw-press and this may be of particular advantage where distilled lime oil is to be the main or only product. The screw-press is a smaller piece of equipment and easy to strip down and adjust, but requires adjustment at regular intervals if its crushing efficiency is to be maintained. It is possible with a screw-press to apply too much pressure and to produce a raw juice which will not settle properly under gravity no matter how long it is left to stand.

As indicated, a triple roller mill of the size described should be capable of crushing 100 tons of fruit in a week. In order to obtain an efficient separation of top pulp from the clear juice, it is inadvisable to add to one vat, more than four consecutive days production of 'raw juice' from crushing. Generally, the volume of this juice approximates 40-45% of the fresh fruit, thus 1 ton of fruit should yield about 100 gallons of expressed fluids. The roller mill should produce 5 to 6 thousand gallons of 'raw juice' over 4 days and 4 or 5 vats of this capacity would be required to cope with this level of production.

Processing lime oil and lime juice

The juice extracted by the crusher should pass through screens for the removal of coarse pulp and pips. The waste skins can be removed either by a suitably placed conveyor, or by a removable waste box. The former is preferable, particularly when working at maximum throughput of the machine.

In the West Indies, the raw juice is usually collected in wooden boxes (coated with paraffin wax), or a stainless steel box in one case, placed under the mill. The raw juice is screened through stainless steel mesh (16 mesh and 32 mesh). Screening is often done by hand brushing, although a rotary stainless steel screen is used in one factory.

Crusher and screens must be kept scrupulously clean and scrubbed down thoroughly after each days crushing.

Settling vats

Settling vats are normally wooden and cylindrical with removable covers on the top so that they can be closed and sealed when raw juice is settling.

Vats may be constructed of any wood which will not taint the lime juice and oil. White oak has been used in the West Indies and is thought to have a life of about 7 years. After that time wood borers will have made white oak vats unreliable. Harder woods such as wallaba and greenheart have been used with more success but both are more expensive and difficult to work. However, in the long-run they are probably to be recommended.

Lime setting vats are not usually coated on the inside although the outside may be painted. One company has been experimenting with an epoxy resin based paint on the inside of setting vats but the results of these tests are not known.

The cleanliness of lime settling vats is of paramount importance in the production of high quality lime products. Vats should be scrubbed out and steamed at regular intervals. When not in use for settling they should be kept full of water to which potassium (or sodium) metabisulphite has been added and the lids tightly closed.

Raw juice is fed into the settling vats by gravity or is pumped. It is worth remembering that if electricity is unreliable a manual and/or mechanical juice pump is essential.

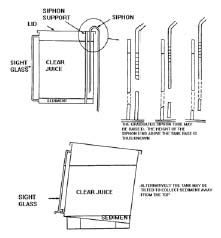

The valve through which settled juice is drawn-off should be as near to the bottom of the vat as is practicable in order that settled juice is not wasted. The height of the tap above the bottom of the vat will depend on the amount of 'bottom' pulp which accumulates during settling. It is possibly worth having several taps at varying heights above the bottom of the vat eg 3", 5", 9" to ensure that one can draw off as much settled juice as possible.

The settling vats are also equipped with a bottom drain valve through which the still charge can be allowed to flow into the still under gravity (if it does not have to be pumped), and through which the vat can be drained during washing.

The sizes of the lime crop, settling vats and still should, if possible, be related, bearing in mind that:

• it is not advisable to fill a settling vat and thus disturb the settling, over more than a couple of days.

• the top pulp from a vat should ideally make one still load for distillation.

Working back from the still capacity, a still with a working volume of 500 gallons will take the contents of a 1700 gallon settling vat (assuming that 30% of the settling vat volume is distilled and 70% is settled lime juice). With efficient crushing a 1700 gallon vat would be filled with the raw juice from 15-16 tons of limes. If limes are coming in at 10 tons/day then the vat will be filled within 2 days. For the beginning and end of the season the vats of 850 gallons may suffice and clearly a balance should be struck between large and small vats.

It is not good practice to keep adding fresh raw juice to vats which are partially full and have started to settle. The settling is disturbed and the pulp which tends to break down during settling can form a fine cloud which prevents a clear settled juice being obtained. It is not advisable to take more than 2-3 days to fill a vat.

It is not recommended that top pulp be stored before distillation after the settled juice has been drawn off, but this practice is adopted in some factories owing to lack of distillation capacity and/or the use of very large capacity settling vats. Ideally, one would like to distill top and bottom pulp from a vat as soon as the settled juice has been run off.

Addition of preservative is required, (sodium metabisulphite) to prevent fermentation if the drum is to be stored or transported over a period of several months. Alternatively, there may be local outlets for soft drink preparations where different requirements are needed, such as bulk-storage. For shipment overseas, the single strength juice will be costly to transport in drums and the juice may be concentrated to about 5 times for economy in transport costs. This requires expensive equipment and consequently a high production level of juice is needed to offset the capital costs of concentrators.

Lime juice

'Clarified' juice is settled or racked juice which as been 'polished' by passing it through a clarifying filter. It is probably worth doing this to all settled juice in order to be assured of a standard 'bright' product.

The settled juice is shipped in wooden casks (coated internally with paraffin wax) or suitably coated metal drums and is preserved with SO2. It is important that wooden casks be washed thoroughly and steamed before waxing. Coopering is important as juice losses can be high if casks are not coopered up tight.

If the juice is to be stored for a considerable length of time, 900ppm SO2 is recommended (350ppm is the legal limit in the UK for potable liquids but as single strength lime juice is greatly diluted before consumption this level of SO2 does not present a problem).

The potassium (or sodium) metabisulphite is best dissolved in water in a special tank and the solution of SO2 of known strength admitted into the lime juice casks or drums.

Settled lime juice (preserved with SO2) has been shipped successfully from the West Indies to the UK in 250 gallon Transit-tanks which are constructed of high density polythene supported in a steel frame.

Lime oil

The top/bottom pulp charge is distilled to obtain the lime oil. A good quality lime oil is generally one which exhibits a low optical rotation (ca + 38°). The optical rotation decreases as the duration of the distillation increases. Aroma/flavour quality of lime oil is associated with an increase in oxygenated constituents. Some of the oxygenated compounds are produced during the distillation when the lime oil is exposed to high temperatures in an acid environment.

The distillation unit should comprise of a still pot, about 750 gallons working capacity, together with condenser and oil collection systems. Stainless steel is preferred for construction of the equipment, as it is resistant to corrosion and non-reactive to the oil. A suitable boiler for steam generation will be required and this should have an output of at least 500lbs of condensed steam an hour, high pressure steam is not required. An adequate volume of steam generated at low pressure is the main requirement.

The still contents should be warmed-up on the closed coil until distillation commences and then the closed coil is turned off. Distillation is continued by use of the open steam coil ('sparge'), which if lagged properly has the effect of maintaining the liquid level in the still, at about the same height throughout the distillation. In this way the possibility of the charge overheating is avoided. Distillation rate, and time of distillation is dependant on still and charge size.

Still cleanliness is very important. The inside of the still should be regularly scrubbed out to avoid the build up of lime residue on the walls and more particularly the steam coils. After cleaning the still should be steamed out until no unwanted odours remain.

To avoid a build up of pulp inside the open steam coil a slight flow of steam is passed through it whenever the still contains a charge.

Distillation equipment

The still works at only a little above atmospheric pressure (stills will often be equipped with safety valves which are set at 5psi.

It is occasionally worth considering using a water sealed top, as the gasket seals which are widely used, suffer from the drawback that gaskets wear out and must be replaced. This is not always easy in remote areas.

A multi-tubular stainless steel condenser of the type shown (Figure 1) is the most efficient, providing sufficient water pressure is available.

It is essential that you have an efficient Florentine flask oil separator. The glass Florentine flask (it can be sealed up of course) is useful for seeing what is happening, but they do tend to get broken. A single stainless steel Florentine flask of the type shown in the still diagram should be adequate for most needs (Figure 2).

The darkened areas in the still diagram should be efficiently lagged in order to cut down heat losses.

The steam outlet holes in the open coil are generally arranged so that the steam is admitted slightly downward and towards the centre of the still.

Lime oil storage

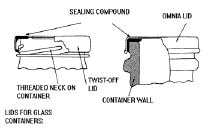

Lime oil may be stored in tanks (stainless steel or glass) and shipped in clear tinplate cans or new metal drums (coated with a lining non-reactive to the oil, such as an epoxy resin). Lime oil deteriorates during extended storage and so should be dispatched to the customer as soon as possible after production.

Containers should be as full as possible to cut down oxidation and securely sealed; the oil should be kept in a cool place and protected from sunlight. Both oil and juice may be marketed through essential oil and commodity dealers, but samples must be provided to them that are representative of the production.

Equipment suppliers

Note: This is a selective list of suppliers and does not imply endorsement by Practical Action.

Small juice extractors and peelers

Kenwood Limited

New Lane

Havant

Hampshire

PO9 2NH

United Kingdom

Tel: +44 (0) 23 9247 6000

Fax: +44 (0) 23 9239 2400

Website: http://www.kenwood.co.uk/

Lehman Hardware and Appliances Inc.

P.O. Box 41

Kidron

Ohio 44636

USA

Tel orders: +1 877 438 5346

Tel enquiries: +1 888 438 5346

E-mail: info@lehmans.com

Website: http://www.lehmans.com

Suppliers of hand operated fruit presses and grinders.

Refractometer

Bellingham + Stanley Ltd.

Longfield Road, North Farm Industrial Estate

Tunbridge Wells, Kent TN2 3EY

United Kingdom

Tel: +44 1892 500400

Fax: +44 1892 543115

E-mail: sales@bs-ltd.com

Website: http://www.bs-ltd.com/

Alvan Blanch Chelworth

Malmesbury

Wiltshire

SN16 9SG

United Kingdom

Tel: +44 (0) 666 577333

Fax: +44 (0) 666 577339

E-mail: info@alvanblanch.co.uk

Website: http://www.alvanblanch.co.uk

Essential Oil Distillation Plant used to extract oil from a variety of crops, herbs and spices using the method of distillation. Capacity: 130-420 kg/hour.

Fruit Pulper/Siever

Used for the extraction of juice or pulp from fruit. Complete with feed chute, removable stainless steel perforated screen, rotary paddle with blades and collecting tray below. Food Groups: Fruit Power: Electric

Distillation equipment

See the Practical Action Technical Brief on Essential Oil

Granite rollers are available from Alexander Stephen Engineering Limited, Linthouse, Glasgow, Great Britain, but the remainder of the crusher would need to be made by a local engineering firm. A mill with rollers 30" long and 12" in diameter can crush at 11/2-2 tons an hour and can be driven by a 5hp motor.

In the running of a lime processing operation a reliable electricity supply is very important. When you consider that conveyors, crushers, washer, juice pumps and boiler (fuel pump, ignition and safety device circuits) may all need electricity to operate. If a reliable power supply is not available, consideration should be given to installing a standby diesel generator.

In the event, that it is not possible to provide an alternative electricity supply, it could be of value to consider, the use of diesel engine(s) to drive the crusher, washer, juice pump, etc and for the boiler to be fuelled with solid fuel (in an emergency).

When a high percentage of yellow limes are being delivered to the factory each day, it is important to crush them on the day they arrive, as they very soon spoil and give rise to losses. It is therefore, of great importance that your crusher can work continuously.

References and further reading

This Howtopedia entry was derived from the Practical Action Technical Brief Processing of Pepper.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_food_processing

Lime Juice Production Practical Action Technical Brief

Lime Juice Clear Cordial Practical Action Technical Brief

Nas naran lime juice Practical Action Technical Brief

Useful addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail: practicalaction@practicalaction.org.uk

web: www.practicalaction.org