Difference between revisions of "How to Build the Vacvina Biogas Digestor"

(→Categories) |

Do Duc Tuong (talk | contribs) |

||

| Line 1: | Line 1: | ||

| − | + | VACVINA biogas is a technology introduced in 1998 by The Center for Community Research and Development (CCRD) belonging to the Vietnam Gardening Association. VACVINA stands for VAC ("Vuon"-Garden, "Ao"-Pond, "Chuong"-Stable) of VietNam. The VACVINA biogas model is developed based on two existing technology in Vietnam: (1) The fixed dome model came from China and India, and (2)The plastic digestion bag model was firstly introduced from Columbia to Vietnam in 1994 by doctor Reg Preston, Rector of the University of Tropical Agriculture. The VACVINA model is an innovative technology <br> | |

| − | The system consists of a | + | The system consists of a digestion tank (septic tank), nylon reservoir bag and inlet, outlet tubes. The digestion tank is a flat-top rectangular underground digestion chamber. The external plastic gas reservoir is made of two to three layers of nylon bag. An ingenious system of inlet siphon allows the new material to be dropped into the surface of the fermenting liquid thus breaking any accumulated scum. The small outlet tank collect liquid waste from the digestion tank through a plastic tube.<br> |

The length of the main bag determines the total digestion chamber volume (a 10 m bag results in a 7 cubic meter digestion chamber). The digestion bag is half buried in a trench and is connected at one end to a small mixing and collection tank and at the other end to a slurry holding pit. The gas reservoir has a capacity of 1,8 m3 and is usually suspended either in the kitchen or the stable (Fig. 3).<br> | The length of the main bag determines the total digestion chamber volume (a 10 m bag results in a 7 cubic meter digestion chamber). The digestion bag is half buried in a trench and is connected at one end to a small mixing and collection tank and at the other end to a slurry holding pit. The gas reservoir has a capacity of 1,8 m3 and is usually suspended either in the kitchen or the stable (Fig. 3).<br> | ||

Revision as of 15:02, 13 August 2009

VACVINA biogas is a technology introduced in 1998 by The Center for Community Research and Development (CCRD) belonging to the Vietnam Gardening Association. VACVINA stands for VAC ("Vuon"-Garden, "Ao"-Pond, "Chuong"-Stable) of VietNam. The VACVINA biogas model is developed based on two existing technology in Vietnam: (1) The fixed dome model came from China and India, and (2)The plastic digestion bag model was firstly introduced from Columbia to Vietnam in 1994 by doctor Reg Preston, Rector of the University of Tropical Agriculture. The VACVINA model is an innovative technology

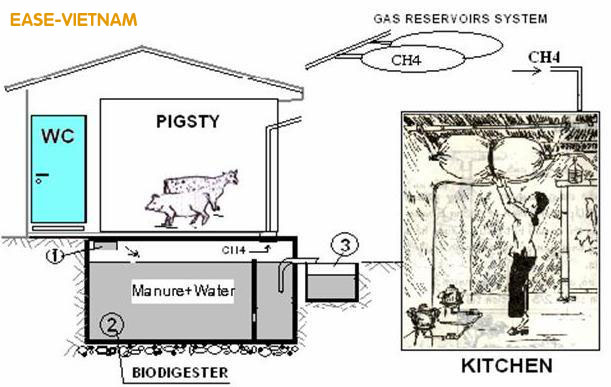

The system consists of a digestion tank (septic tank), nylon reservoir bag and inlet, outlet tubes. The digestion tank is a flat-top rectangular underground digestion chamber. The external plastic gas reservoir is made of two to three layers of nylon bag. An ingenious system of inlet siphon allows the new material to be dropped into the surface of the fermenting liquid thus breaking any accumulated scum. The small outlet tank collect liquid waste from the digestion tank through a plastic tube.

The length of the main bag determines the total digestion chamber volume (a 10 m bag results in a 7 cubic meter digestion chamber). The digestion bag is half buried in a trench and is connected at one end to a small mixing and collection tank and at the other end to a slurry holding pit. The gas reservoir has a capacity of 1,8 m3 and is usually suspended either in the kitchen or the stable (Fig. 3).

As organic material is fed into the digestion bag, it slowly travels down the length of the tube while the fermentation process occurs and is then expelled at the other end as digested slurry. The biogas produced accumulates in the main bag and, through gravity as well as pressure, finds its way to the gas reservoirs. Thus biogas is stored partly in the digestion bag and partly in the gas reservoir. Users can easily judge the quantity of gas available by the level of inflation of the bags.

Plastic bag digesters are inexpensive, easy to install and operate and scum formation can be controlled easily by gently slapping the scum to make it sink to the bottom. On the other hand, the polyethylene bags are somewhat fragile they can be perforated or torn and their life expectancy is but 3-5 years. They must be protected from wandering animals and also from sunlight as UV rays will degrade the plastic. In addition, the model requires a large area of 10-15m2 near the animal stable.

This is a problem for many households in the Red River Delta where household compound is not large enough to allow its installation.

Video link

Video clip: http://www.youtube.com/watch?v=ne3RdAmPIbw