How to Build Earthquake Resistant Housing

Contents

Earthquake Resistant Housing - Technical Brief

Short Description

- Problem:

- Idea:

- Difficulty:

- Price Range:

- Material Needeed:

- Geographic Area:

- Competencies:

- How Many people?

- How Long does it take?

Introduction

The fundamental need for shelter can be easily recognised: people must have protection from the elements, somewhere to grow as a family, a place to work from and a home to call their own. In many countries people do not have the resources to buy houses built by professionals but rely on their own labour, using local materials to build their homes gradually. People make improvements and extend their houses as family requirements change and resources permit.

Disaster strikes

On the evening of 29 May 1990 Alto Mayo (see Figure 1) was struck by an earthquake measuring 6 on the Richter scale. The effects were felt in an area covering more than 8000 square kilometres, damage was sustained by 8000 houses with nearly 3000 irreparably damaged. These figures only begin to suggest the magnitude of loss felt by local communities. In the district capitals of Habana and Soritor, eight out of ten houses were destroyed.

Rebuilding communities

Practical Action is an organisation focused on achieving long-term, sustainable development and does not undertake disaster relief. However, Practical Action (then called ITDG) was well placed to assist in the reconstruction efforts; staff who worked in the area were well known by local people. In partnership with local organisations Practical Action had established working relationships and friendships that enabled them to quickly become involved in preparing a reconstruction plan.

Relief intervention was the remit of Caritas Peru, a church organisation supported by an international network of organisations concerned with humanitarian work. Given the disruption to daily lives caused by the earthquake, Practical Action recognised the opportunity to create long-term benefit and was careful to consider how people could participate in rebuilding homes. Reconstruction had to continue at a pace that people could afford and at the same time meet people's need for economic survival alongside their need for shelter. Practical Action had to be certain that activities proceeded in accordance with local people's priorities and would not be dominated by external pressures and agendas.

Practical Action's intervention in the reconstruction began in the town of Soritor (see map). This settlement was chosen as the starting point for two reasons: the extent of damage sustained in the town was relatively high as was the level of community organisation. Social structures existed that enabled Practical Action to consult with the local community despite the disruptive impact of the earthquake. After community meetings Practical Action engineers and social scientists developed a reconstruction plan for the Alto Mayo region which was then presented to the local authorities.

Getting started

The community based organisation FEDIP (el Frente de Defensa de los Intereses del Pueblo de Soritor) had evolved in the preceding years, during times of economic hardship, to negotiate prices and represent the interests of local producers: their organisational skills and knowledge proved to be critical in achieving project success. Soritor is divided into six neighbourhoods; each of these had an existing neighbourhood committee that organised collective meetings to discuss reconstruction efforts. FEDIP’s experience of fighting for the interests of small-scale agricultural producers meant they were well aware of the realities of local life with a strong committee structure, they were able to seek the views of, and represent, people at district, provincial and departmental levels.

With financial support from the British Embassy and the Overseas Development Administration of the United Kingdom (now the Department for International Development) backed up with technical documentation from university researchers and photographic evidence of houses built in Huacucho, Duval Zambrano and Hermelando Aliaga, of Practical Action, set about consultation exercises with the 5000 inhabitants of Soritor.

Planning in partnership

During the initial six months after the earthquake, efforts focused on recording people's ideas, aspirations and concerns in order that these could be included in the Alto Mayo Reconstruction and Development Plan. Of equal, or perhaps greater significance was the process of drawing people together to share their opinions. This process enabled Practical Action and their project partners to develop practical working relationships and organisational structures to forge links with the wider local population. The reconstruction plan was not seen as a quick-fix solution to the very apparent housing problems but as an opportunity to link post-disaster efforts directly into long-term development activities.

Beneficiaries

With such a large and immediate need for rebuilding it was crucial for Practical Action to be confident that the people who would benefit from the project were those who needed it most. Practical Action relied heavily on FEDIP and Caritas to ensure that selection of project beneficiaries was undertaken in an objective manner and was seen to be fair. Initially the feeling locally was that everyone was a victim of the earthquake and that everyone should therefore benefit equally from incoming aid. However, it soon became apparent that some people had more resources at their disposal than others.

Practical Action staff did not decide who the project beneficiaries would be, though staff were often intermediaries in complex negotiations with various parties. Neighbourhood committee members were consulted first, and were asked to write down a list of. 30 - 35 heads of households. The people on that list were subsequently classified by Practical Action's Community Liaison Officer into four categories:

- rich farmer e.g. 5 or more hectares of rice-growing land.

- employee e.g. teacher.

- poor farmer e.g. less than 2 hectares.

- poorest e.g. landless, widow.

This list of people was then passed to the local order of nuns who made final adjustments and decided who the beneficiaries should be.

One immediate problem Practical Action had to tackle was the widely held belief that external interveners like Practical Action and Cáritas would provide all the materials required; 1990 was an election year and politicians seeking election might have encouraged people to believe that new houses would be freely available. A high level of expectation existed - in some people’s minds that Practical Action’s role was as a housing provider: they should build the houses for people and hand over keys upon completion. Practical Action strongly believes that it is more useful to help people to help themselves and to assist in building technological capacity in order that people benefit in the long term, after Practical Action's project is over.

Building choices

During early discussions it was not clear which building technologies would be chosen. It could be argued that earthquake resistance was the only criterion governing the technical choices to be made. However, Practical Action believes that sustainable development depends upon a good deal more than predetermined technical solutions.

Using drawings, manuals, photographs and videos from pilot housing projects in other regions of Peru, project staff were able to demonstrate building technologies. A series of meetings resulted in an increasing level of understanding between project partners of their respective roles and the nature of support that was being offered; as well as linking needs and priorities to design and technology.

The technologies used to build houses cannot be viewed in isolation from their social or economic context. Although Practical Action staff could see benefits in working with improved, local technologies, they were also aware that people tend to prefer ‘materiales nobles’ (noble materials), such as fired brick and reinforced concrete. These modern technologies are of higher status, greater durability and longer-term financial value. However, affordable, earthquake-resistant building technologies were required for rebuilding; many of the rammed earth ‘tapial’ houses failed in the earthquake but ‘quincha’ (a type of wattle and daub) had shown its inherent earthquake resistance. The need for affordable, locally available, safe shelter won the argument: Practical Action project engineers and local men and women decided that improved quincha was a preferable and practicable technology choice.

|

Olympia Guerra Olympia Guerra became known in her neighbourhood as La Maestra - The Craftswoman. She lived as a single woman in the village of Jepelacio and worked in a neighbourhood building team with four other women and four men. She felt that operating in a small group was beneficial as everyone had to do their share of the work. Olympia was taught by a skilled craftsman who was employed by ITDG to assist in the reconstruction project. With newly developed skills Olympia learnt how to build a concrete base for her own house and then went on to help others do the same. Practical Action were keen to employ Olympia as an extension agent but the strongly held belief that building is a man's job, coupled with peer pressure, is said to have made this impossible. Instead she participated in the team's own workload and played an active role in the reconstruction of her own and other neighbours'houses during a programme of activities lasting more than six months. |

Origins of quincha and technology development

Quincha technology has been used in parts of Peru for many centuries. Traditionally, a quincha house would have a round pole frame which was set directly into the ground, infilled with smaller wooden poles and interwoven to form a matrix which is then plastered with one or more layers of earth. Since 1535, the Spanish colonisers employed quincha for building domes on top of massive earthen church walls. The 1746 earthquake, which had a devastating impact upon the city of Lima, triggered much wider use of quincha. After that earthquake, the governors of Peru decreed that any construction above ground floor level should be built of quincha. One can still find older houses in Lima with earth walls at ground floor level and a quincha structure above.

In the Alto Mayo region, a large proportion of the population have immigrated from the mountainous region of Cajamarca where massive earthen architecture predominates. The collective memory of these people did not include experience of earthquakes and their technology choices reflected their earthquake-free homelands.

An earthquake in 1970 produced renewed interest in earthquake-resistant building technologies. During the 1980s researchers at the Catholic University, the National Engineering University and the National Institute of Housing of Peru, supported by the United States Agency for International Development, investigated ways of improving upon traditional building materials and housing systems: they focused in particular on quincha technology.

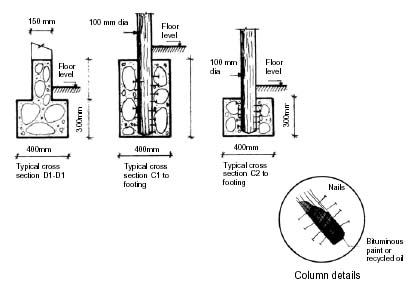

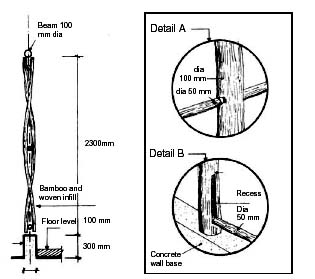

The results of investigating quincha technology in a university environment were new designs with increased earthquake resistance. Research highlighted methods of improving durability and creating standardised construction units. Housing units were designed to include uniform measurements of 1.2m between structural columns which were made of square timber sections (200mm x 200mm).

Practical Action engineers drew on this academic research when presenting the improved technology to the men and women of Soritor. Technical details were soon adapted once Practical Action project engineers and technicians started work in Alto Mayo. For example, timber poles replaced the square columns as they are more readily available and do not require machinery or labour to process them from their raw state.

Figure 5: Plan view ©Practical Action/Duval Zambrano/J. Cuizano

Improved quincha has the following characteristics over and above traditional quincha:

- concrete foundations to give greater stability.

- wooden columns treated with tar or pitch to protect against humidity, concreted into the ground with nails embedded in the wood at the base to give extra anchorage.

- use of concrete wall bases to prevent humidity affecting the wood and the canes in the walls.

- careful jointing between columns and beams to improve structural integrity.

- canes woven in a vertical fashion to provide greater stability.

- lightweight metal sheet roofing to reduce potential danger to occupants from falling tiles.

- nailing of roofing material to roof-beams; tying of beams and columns with roof wires to guard against strong winds and earth movements.

- roof eaves of sufficient width to ensure protection of walls against heavy rains.

Improved quincha has many advantages in addition to earthquake resistance. Easy access to materials and low cost were of primary concern to Practical Action and to local men and women. The local availability of timber poles, bamboo and earth means that improved quincha is more suited to a self-help building programme than many alternatives.

People's participation

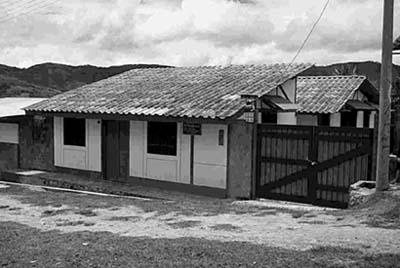

After the initial project phase Practical Action planned to demonstrate improved quincha in a real project (seeing is sometimes believing). A community building was erected in central Soritor. It took six months to build this structure, which resulted in this technology being nicknamed delayed quincha rather than improved quincha.

However, the slow approach was deliberate. It takes time to fully involve a diverse and numerous group of people in a construction project. A team of ten to fifteen men and women from different neighbourhoods were involved in the construction process every week. This led to greater awareness and an increased understanding of how the technology was used: many people learnt the details of construction and the skills required to successfully complete an improved quincha building. In addition to manual labour the community also provided the bulk of materials which were sourced locally.

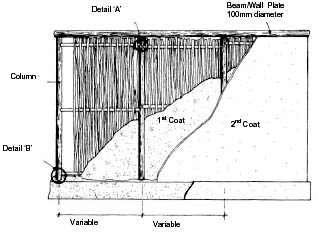

Practical experience of working with this technology during the demonstration meant that Practical Action staff and members of the community were able to learn by doing. This resulted in new thinking and some changes: for example, the first coat of plaster put onto the woven infill panels was found to crack, so rather than allow cracks to develop naturally, the first layer of plaster was deeply scored to allow for the shrinkage upon drying and to provide a better grip for the second coat of plaster.

|

Specifications Concrete pad and strip foundations: Render1st coat - mud: straw |

In the Alto Mayo region self-help construction remains the predominant method of building houses. Individual household members help each other to construct their homes and also help other households in the same community. If structures are for communal use then every household in the community assists in the building process. This has recently become less common as more people have formal jobs and are unable to devote their own time. Often craftsmen will be employed on a casual basis to complete specialist tasks and oversee the building process. Practical Action’s ways of working had to reflect traditional approaches whilst taking into account the constraints of modern life.

Building the community centre introduced the improved quincha technology to those directly involved in the construction process as well as to the many observers who stopped by to watch the work progress. The opportunity to collaborate in a practical task also created understanding between project staff, local people, organisations and authorities.

Figure 9: Careful jointing between columns and beams improves structural integrity ©Practical Action/Chris Martin

Designing a new home

Following the demonstration phase a series of activities concentrated on designing houses with people. By working with men and women in small groups, architectural and building professionals used colour coded wooden blocks to model design options and produced plans for a core housing unit. It was essential that the design remained sufficiently flexible so as to be adaptable to specific family requirements, to incomes, to materials available, to land features and to any unexpected factors which may arise.

By modelling their ideas people could create their preferred house in miniature. Their design was drawn up by an architect and then adjusted once more with input from household members. These activities were undertaken within specific neighbourhoods and served to plan the subsequent work, identify materials required and engage people in the whole reconstruction process.

Building work started once materials had been gathered and transported to all the group members plots. Groups of 20 - 25 people formed construction teams; they worked in turns on each other’s plots until all the houses were completed. This work usually proceeded at weekends thus allowing for family responsibilities, agricultural work and people's jobs during the week. When people were available, work would also proceed during week days.

At the beginning of the project it was assumed that people could provide materials such as aggregate, sand, timber and bamboo in addition to any salvaged materials from their damaged dwelling. If an individual member of the group had insufficient resources to contribute others would often assist. When individuals had no agricultural land from which to harvest bamboo or timber they would have to transport materials from distant forests.

Transport was often a problem for people; in some cases the local authorities or other donor projects would lend their vehicles for transportation of sand from the local river bed. ITDG and Caritas provided sufficient additional materials to the people in most need (galvanised iron sheeting, nails and cement) to build a 30m2 housing unit.

Despite these efforts to explain and promote this technology scepticism towards improved quincha remained - it was after all an unknown technology that had little social standing (seeing is not always sufficient to be convinced of the value of new technologies, especially when resources are very limited). A significant factor in improving the popularity and acceptance of improved quincha technology was another earthquake, in April 1991. The total toll on local housing amounted to 17,000 damaged units. The first locally built examples of improved quincha demonstrated their improved resistance to the impact of earthquakes and served to convince many more people of the appropriate nature of this technology.

Project impact

The direct intervention in reconstruction activities by Practical Action and Caritas ceased in March 1994 and had, by that time, resulted in 558 improved quincha houses being built in the Alto Mayo province. There are also many thousands of improved quincha houses which have been built by men and women, independently of the project. The 1993 national census estimated that quincha formed just 7% of the national housing stock but within the project area this figure rose to nearly 30%.

|

|

The accurate costing of self-build houses can be a little misleading unless people are able to put a monetary value on their own involvement; this is not often the case. However, a comparison cost of an improved quincha house and a brick house gives an indication of the relative prices of these two technologies. The estimated cost of a finished building (30m2) of improved quincha including doors, windows, floor, ceiling, external plaster and painting (at 1996 prices) is 3,313 soles or US$1,299. The equivalent structure made of brick would cost 13,772 soles or US$5,400 - the need to contract skilled labour is a significant proportion of this cost.

In conclusion

ITDG was directly involved in the reconstruction of several hundred houses but there are several thousand more in the area which are made of improved quincha or a variation of it. Technology development continues. Practical Action’s intervention is not the only force driving technology change. People’s needs, knowledge and technical capacity, local resources, political and personal agendas are all factors promoting change and technological development.

Innovations in quincha technology are no exception; the ‘improved quincha’ housing promoted by ITDG and partners, can be seen widely in Alto Mayo but it differs in design and detailing, reflecting the materials, skills and individual priorities of the owners and builders. In practical development projects it would be easy to imagine that the end product is the main goal: the end result needs to be a comfortable, affordable and safe house. However, the way in which you work towards that practical goal can have an important impact on people’s lives. ITDG’s staff and partners showed the need and ability for patience, flexibility and perseverance: people and processes are complex. Practical Action seeks to ensure control of the agenda remains with the community and to work in partnership, ensuring people understand the choices they are making and developing their long-term technological capacity.

Reference and further reading

This Howtopedia entry was derived from the Practical Action Technical Brief Earthquake Resistant Housing in Peru" written by Lucky Lowe and produced by ITDG (now Practical Action) in 1997.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_construction

- Mud Plasters and Renders Technical Brief, Practical Action

- Building with Bamboo: A Handbook by Jules J. A. Janssen, ITDG Publishing, 1995, ISBN 1 85339 203 0

- Los Planes de Preparación de Emergencia, Technical Brief, Practical Action Latin America

- Emergency Preparedness Plans Technical Brief, Practical Action Latin America

- Risk Mapping, Technical Brief, Practical Action Latin America

- Terremotos en el Trópico húmedo. La gestión de los desastres del Alto Mayo, Practical Action Latin America

- Estructuras Resistentes a Desastres Practical Action Latin America

- Practical Action Latin America

Casilla Postal 18-0620, Lima 18, Peru. Tel: (+51) 1 4467324/4447055, Fax: (+51) 1 4466621 - De terremotos, derrumbes e inundados. LA RED

- Red de Estudios Sociales en Prevención de Desastres en América Latina (LA RED) http://www.desinventar.org/

- Affordable, Quake-Proof Adobe Housing in Peru, IDRC - International Development Research Centre http://www.idrc.org.sg/en/ev-2689-201-1-DO_TOPIC.html

- Volcanoes and earthquakes - Disaster Prevention in Latin America, IDRC - International Development Research Centre http://www.idrc.org.sg/en/ev-2686-201-1-DO_TOPIC.html

- IDRC - International Development Research Centre

P.O. Box 8500 Ottawa, Ontario, Canada K1G 3H9. Tel: +1 613 236 6163, Fax: +1 613 567 7748

The Canadian organisation IDRC (International Development Research Centre) CRDI (Centre de recherches pour le développement)

Useful addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail:practicalaction@practicalaction.org.uk web:www.practicalaction.org

Categories

[[]]- Medium

- More than 200 US$

- More than 5 Persons

- Global Technology

- Construction

- Community

- Crisis Management

- Education

- Equipment Design

- Prevention

- Soil

- Global

- Montaneous Environment

- Rural Environment

- Urban Environment

- Bricks

- Clay

- Cement

- Concrete

- Wood

- Household

- Village

- Neighbourhood

- School

- Principles

- Requested translation to Spanish