How to Process Pepper

Contents

Short Description

- Problem: how to make out of harvested pepper spikes a sellable high quality final product

- Idea: description of the differents steps of processing and the tools necessary to do it

- Information Type: Application

- Difficulty: medium

- Price Range: high

- How Many people? one farmer family

- How Long does it take? 1-3 weeks depending on the drying equipment and the climatic conditions

Harvesting

By definition, 'processing' does not involve harvesting. However, one cannot produce a good product from badly harvested materials. Correct harvesting techniques could be said to be the most important factor in the production of a high quality final product. The main problem is immature harvesting.

Immature harvesting

The main reasons for immature harvesting is the fear of theft. If the crop is picked correctly when it is mature the higher yields and higher value of the final product may offset the losses due to theft.

Through extension officers, correct harvesting should be encouraged.

However sometimes immature pepper receives a higher price than mature pepper due to purchase by food processors due to its higher percentage of flavour components.

Correct harvesting

The pepper spike should be picked when one or more of the berries start going yellow/orange. The berries should be hard to the touch.

Threshing

In most countries the harvested pepper berries are removed from the spikes before drying. This can be done by hand, beating with sticks or trampling on the pepper spikes.

Cleaning

A clean product is essential. The major problem for the export of pepper by small-scale farmers is the production of a sufficiently clean product.

The first step is to remove dust, dirt and stones using a winnowing basket, see Figure 1. This can be done in the same way as for rice. Someone used to this work can remove the dirt, dust and stone quickly and efficiently (they can clean over 100kg of pepper in an eight-hour day).

There are machines that can be bought or made that can remove the dust, dirt and stones. However, for a small-scale unit, winnowing the crop by hand is the most appropriate system.

After winnowing the crop needs to be washed in water, for quantities of up to 50kg a day, all that is needed is two or three 15 litre plastic buckets. The crop should be washed by hand and drained two or three times. For larger quantities a 1m³ sink/basin with a plug hole needs to be constructed. This can be made out of concrete. However, the water must be changed regularly to prevent recontamination by dirty water. Only potable water should be used.

The pepper berries can be blanched before drying by dipping them in boiling water for ten minutes. This accelerates the drying and browning of the berries. However, the fuel costs may be prohibitive.

Drying

This is by far the most important section in the process. The inability to adequately dry the produce will, at the very least, slow down the whole process and possibly lead to mould growth. Any pepper with even a trace of mould cannot be used for processing. The sale value of mouldy pepper can be less than 50% the normal value. In extreme cases, the whole crop can be lost. To get the full black colour of dried pepper it needs to be dried in direct sunshine. This can be achieved by sun drying, solar drying or in a combined solar and wood burning drier.

During the dry season, sun drying is usually adequate to dry the produce. The simplest and cheapest method is to lay the produce on mats in the sun. However, there are problems associated with this method. Dust and dirt are blown onto the crop and unexpected rain storms can re-wet the crop.

A solar dryer avoids these problems. The simplest type is the cabinet solar dryer, see Figure 1, which can be constructed out of locally available materials (eg bamboo, coir fibre or nylon weave).

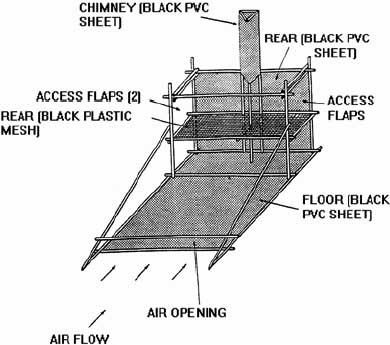

For larger units (over 30kg/day an 'Exell Solar Dryer' could be used, see Figure 2. However, the construction costs are greater and a full financial evaluation should therefore be made to ensure that a higher income from better quality spices can justify the additional expense.

During the wet season or times of high humidity, which often coincides with the harvest of the spices, a solar dryer or sun drying can not be used effectively.

An artificial dryer, which uses a cheap energy source is necessary. This may be a wood or husk burning dryer or a combined wood burning and solar dryer. Figures 3-6 show a combined wood burning and solar drier which is based on the McDowell Dryer and has been used in Sri Lanka.

Figure 3: Combination wood and solar dryer, complete with solar cover

Over drying

Care needs to be taken to prevent over drying of the crops which results in the loss of flavour components. A drier operator will soon learn how to assess the moisture content of the crops by hand. The final moisture content should be less than 10% wet basis.

Grading

In some cases the crop needs to be graded, eg high quality packaged products.

Pepper is graded by size, colour and relative density. Colour grading will have to be done by hand. Machines can be bought or made that will grade the pepper according to its size or relative density. However, a trained person with a winnowing basket is more appropriate for small-scale production.

Grinding

Grinding may also add value but must be done carefully as there are difficulties. A whole, intact product can be easily assessed for quality whereas a ground product is more difficult. There is a market resistance to ground produce due to fear of adulteration. This can only be overcome by producing a consistently high quality product and gaining the confidence of customers. There are basically two types of grinders - manual grinders and mechanical grinders. A grinding mill has to be placed in a separate and well-ventilated room because of dust.

Manual grinding mills

There are many manual grinders that could be used to grind pepper.

An experienced operator can grind about 20kg in an eight-hour day. However, this is hard and boring work. A treadle or bicycle could easily be attached to the grinder, making the work easier. With this system one person could grind about 30kg in one day.

Work needs to be done to find out the degree of fineness the consumer wants. The grinding mills then need to be set so that they produce the desired ground product.

For small-scale production (up to 100kg/day, a series of these grinders is all that is needed. For larger scale production units, a mechanical grinder would be required.

Mechanical grinding mills

Horizontal plate, vertical plate or hammer mills are suitable for grinding pepper. A grinding mill has to be placed in a separate and well-ventilated room because of dust.

As above the grinding mill needs to be adjusted so that it grinds the pepper to the desired fineness.

Packaging

Packaging material

Packaging of pepper especially if it is ground requires polypropylene. Polythene can not be used as the flavour components diffuse through it.

Simple sealing

The bags can be sealed simply by folding the polypropylene over a hacksaw blade and drawing it slowly over the flame of a candle. However, this extremely uncomfortable as the hacksaw blade heats up and can burn the hands of the operator. However, this is a very common technique.

Sealing machines

A sealing machine will speed this operation up considerably and produce a much tidier finish (which is very important).

The cheapest sealing machines have no timing mechanisms to show when the bag is sealed and they have a tendency to overheat.

Sealing machines with timers are desirable. The machines come in many sizes. For most work an 8 inch (20cm) sealer is sufficient. Eye catching labels should be sealed above the product in a separate compartment and holed so the package can be hung up in the shop.

Storage

A well designed and secure store is essential. The optimal conditions for a store are a low temperature, a low humidity and free from pests. The store should be located in a shaded, dry place. To keep humidity as low as possible only fully dried products should be stored in it. The produce should be checked regularly and if it has absorbed too much moisture it should be dried again.

To prevent rodents entering, the roof should be completely sealed. Mosquito netting should be placed over the windows and doors should be close fitting.

Standards

|

. |

moisture content % by weight Max |

extraneous matter % by weight Max |

lights % by weight Max |

pinheads % by weight Max |

|

International Standards Organization |

12.0 |

1.5 |

10.0 |

4.0 |

|

British Standards |

12.0 |

1.5 |

10.0 |

4.0 |

|

American Spice Trade Association Standards |

12.0 |

1.0 |

4.0 |

. |

Other products of pepper

White pepper

To produce white pepper the pepper berry is not harvested until it is bright red. The red berry is detached from the spike and soaked in gunny bags in a stream for over a week. The water in the stream should be clear to prevent discoloration. After removal the bags are trampled on until the pericarp is removed. The white peppercorns are thoroughly washed and dried.

Decorticated black pepper

This is black pepper that has had its outer skin removed mechanically. It is used as a substitute for white pepper when white pepper is in short supply.

Green pepper

Green pepper is when immature pepper berries are artificially dried or preserved in brine, vinegar or citric acid. They are popular in France.

Pepper oleoresin

This is extracted from black pepper by solvent extraction and is used to flavour foods.

Black pepper oil

The pepper is crushed and then undergoes steam distillation.

Pickled green pepper

Immature green pepper is pickled in vinegar or brine. This is very popular in France and West Germany.

Freeze dried green pepper

This is made in West Germany from imported green pepper corns, preserved in brine.

Rose pepper

This is when over ripe red pepper berries are preserved in brine, vinegar.

References and further reading

Drying of Foods, Practical Action Technical Brief

Small-scale Drying Technologies, Practical Action Technical Brief

Solid Filling and Packaging, Practical Action Technical Brief

Packaging Foods in Glass, Practical Action Technical Brief

Processing of Black Pepper, ITDG Food Chain No3

Spice Plants, M. Borget, 1993, CTA/Macmillan

This Howtopedia entry was derived from the Practical Action Technical Brief Processing of Pepper”.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_food_processing'

Usefull addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail: practicalaction@practicalaction.org.uk

web: www.practicalaction.org

Equipment suppliers

Note: This is a selective list of suppliers and does not imply Practical Action endorsement.

Milling equipment is listed in the Small-scale Spice Processing Practical Action Technical Brief Packaging equipment is listed in the Solid filling and Packaging Practical Action Technical Brief

Udaya Industries Uda Aludeniya

Weligalla

Gampola

Sri Lanka

Tel: +94 8 388586

Fax: +94 8 388909

Pepper Thresher. This machine removes berries from pepper spikes using a rotating drum with spikes. It has a 2kw electric motor or diesel/kerosene engine. Capacity 500-700 kg/hour. Diesel or electrically powered.

Categories:

- Example

- Easy

- Medium

- Difficult

- High Technology

- Dangerous

- Less than 10 US$

- Less than 50 US$

- Between 50 and 200 US$

- More than 200 US$

- One Person

- Up to 5 Persons

- More than 5 Persons

- Global Technology

- Local Technology

- Urban Environment

- Montaneous Environment

- Forest Environment

- Temperate Climate

- Tropical Climate

- Arid Climate

- Monsoon Climate

- Water

- Energy

- Agriculture

- Pest control

- Soil

- Forest

- Food Processing

- Health

- Ideas

- Small Business

- Products

- Construction

- Transportation

- Community

- Mechanics

- Informatics

- Communication

- Principles

- Application

- Prevention

- Recycling

- Crisis Managment

- Plastic container

- Ashes

- Oil

- Garlic