Water Supplies for Food Processing

Contents

Water Supplies for Food Processing - Technical Brief

Introduction

Food and water are two of the relatively few items that people take into their bodies each day in order to stay alive (air and sometimes medicines being others). It is therefore essential, that food processors take the utmost care to prevent their products from becoming contaminated and causing illness or even the death of their customers.

Foods are naturally contaminated with a wide range of bacteria, moulds and other organisms that can cause illness, but these are destroyed or prevented from growing during food processing when it is properly carried out.

Three potential sources of contamination that can make properly processed foods unsafe are water supplies, unclean equipment and the operators in the production unit. This technical brief examines ways of ensuring that the risk of contamination from these sources is minimised.

Most countries have laws governing the hygienic requirements of food factories and food handlers. These should be checked during the planning stage of a food processing project.

Water supplies

Water is used for cleaning equipment, cooling containers and as a component of some foods. In each case only potable water should be used, it may therefore be necessary to treat water before it is used. There are two types of treatment: removal of suspended soils and removal/destruction of micro-organisms.

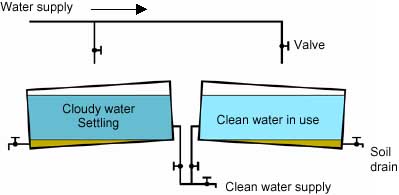

Suspended soils can be removed by allowing them to settle out in settling tanks, see Figure 1 and/or filtering the water through specially designed water filters, see Figure 2. Both processes are relatively slow and large storage tanks are necessary if water is needed for washing or incorporation into the product. Water for cooling can be re-circulated. Although some types of water filters also remove micro-organisms, the easiest way of destroying them is to add chlorine solution (5-8ppm final concentration of chlorine obtained by diluting bleach to 0.02-0.04%). Lower chlorine levels (eg 0.5ppm) are needed if the water is to be used in a product to prevent 'off' flavours. Chlorination of water supplies can be simply arranged by allowing bleach to drip, at a fixed rate, into storage tanks or pipelines. The rate of bleach addition is found by experiment, using simple chlorine paper or more sophisticated probes to check the chlorine concentration. A less suitable alternative is to boil water to sterilise it. Water should be heated to boiling and then boiled vigorously for at least 10 minutes. This of course has a high fuel requirement and will therefore increase processing costs.

Figure 1: Double settling tanks arrangement. Clean water is taken from one tank while impurities are left to settle in the other.

Processing equipment

The frequency and type of cleaning depends very much on the type of food being processed. Equipment for dry foods and powder does not require more than a simple brushing down each day whereas equipment that processes meat, milk and some vegetable products may need careful cleaning with both detergents and sterilants every few hours (because these foods can support the growth of potentially dangerous bacteria whereas dry foods cannot).

The type of cleaning depends on the nature of the soils on the equipment. In general, any equipment in which foods are deposited on the surfaces and then heated will be heavily soiled and difficult to clean. Table 1 shows examples of soils which are easy or hard to remove.

|

Soil |

Solubility in water |

Ease of removal |

Typical foods |

|

Sugar |

Soluble |

Easy |

Preserves, fruit juices |

|

Fat |

Insoluble |

Difficult |

Meat, dairy products |

|

Protein |

Insoluble |

Very difficult |

Meat, dairy products |

|

Mineral |

Variable |

Easy to difficult |

Milk |

|

Salts |

Most soluble in acids |

Depending on solubility | |

|

Starch |

Soluble if not heated |

Easy to difficult depending on heating |

Vegetables |

Table 1: Soil removal

Detergents and sterilants

Detergents help remove the types of soils shown in Table 1 and different types are available for different soils. They do not however, destroy bacteria or sterilise the equipment. Sterilants destroy bacteria but do not help remove soils. It is therefore important, for proper cleaning, that soils are first removed with a detergent and the surface of the equipment is then sterilised with a sterilant.

|

Type of detergent |

Action |

|

Alkaline |

Prevents mineral salt build-ups, removes fat. |

|

Neutral |

Used for surfaces that are damaged by other detergents. |

|

Acid |

Removes mineral salt scale. |

|

Solvent |

Removes fat. |

Table 2: The types of detergent are shown in

The effectiveness of all detergents is increased by brushing and warming to 40-50°C (very high temperatures might cause soils to burn onto equipment and should therefore be avoided). Fats require temperatures above 70°C for removal. In practice the choice of detergent may be limited and it is best to try a small quantity of what is available to make sure that:

• it removes the soil

• it does not corrode the equipment

• it does not foam excessively

• it does not leave a taint in foods used afterwards.

References and further reading

This Howtopedia entry was derived from the Practical Action Technical Brief Energy from the Wind.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_energy

http://www.practicalaction.org/?id=technical_briefs_water