How to Process Oilseed on a Small Scale

Contents

- 1 Small Scale Oilseed Processing - Technical Brief

- 1.1 The policy environment

- 1.2 Raw material supply

- 1.3 Marketing

- 1.4 Health and safety

- 1.5 Methods of extraction

- 1.6 Equipment required

- 1.7 Shelling or dehulling

- 1.8 Heating or conditioning

- 1.9 Expelling

- 1.10 Filtration

- 1.11 Production capacity

- 1.12 Equipment suppliers

- 1.13 References and further reading

- 1.14 Useful addresses

- 1.15 Categories

Small Scale Oilseed Processing - Technical Brief

Most countries in the world have large refineries producing cooking oil from a variety of raw materials including maize, sunflower, soya, coconut, mustard seed and groundnuts. These large centralised plants have the advantage of high efficiency and reduced costs due to the economy of scale. Despite this, in many situations smaller scale decentralised oil extraction can prove to be economic and provide opportunities for income generation. Most commonly, opportunities exist where:

• oil produced in the large refineries does not find its way out to more remote and distant rural areas.

• high transport costs are involved in wide distribution of cooking oil so increasing the price of oil.

• small farmers produce oilseeds such as groundnuts for sale to the large refineries which they then buy back, at high cost, in the form of cooking oil but without the valuable high protein oil cake.

• the crude oil is used to produce added value products, most commonly soap.

• more unusual, high value oilseeds are available; examples include Brazil Nuts, Macadamia Nuts.

Figure 1: Sunflowers grown in Kenya ©Practical Action/Morris Keyonzo

The main risks that need to be considered are:

The policy environment

In many countries the oil processing sector is highly politicised and regulations exist which make entering the market difficult and tend to support the monopoly of the large processors. Large refineries may, for example, insist that farmers sell all their seed under a contract. In other cases seed has to be sold to a central Government marketing board, the board also supplying seed for planting. To determine whether small scale processing is likely to be economic it is most important to first investigate the local situation and regulations.

Raw material supply

Clearly there must be sufficient raw material available locally. One factor that will greatly influence the viability of the enterprise will be the amount of credit needed to purchase a stock of seed. The enterprise should aim to keep the minimum stock of seed but always have enough to continue operating throughout the year. This requires considerable working capital.

Marketing

In general more profit will be made if the cooking oil is packed into retail size bottles. In many countries glass or plastic bottles are difficult to obtain and need to be purchased in large quantities so tying up capital. The possibility of using second-hand bottles should be examined as well as selling in drums to local stores. A survey need to be carried out to make sure that the packaging used meets the demands of customers. (eg size of pack, type of container)

The viability of any oil extraction enterprise depends to a considerable extent on the sale of the oil cake for use in animal feeds and other sub-products. Markets for oil cake must be investigated and demand established before processing starts.

Health and safety

As oil processing is classified as a food processing enterprise it will be subject to local legislation. Care should be taken that standards are understood and met. The particular problem of aflatoxins will require attention. Aflatoxins are natural poisons produced by certain moulds that grow on seeds and nuts. They are of considerable concern to oil seed processors and groundnuts are particularly susceptible to contamination. The growth of aflatoxin producing moulds can be prevented by correct drying and by preventing moisture pickup by raw materials in store. It is most important that those considering establishing an edible oil enterprise should be able to recognise aflatoxin producing moulds and understand how to correctly select and store raw materials. If aflatoxin is present very little passes to the extracted oil, the majority will be found in the cake remaining after extraction. Aflatoxin contaminated cake presents a real danger if incorporated in livestock feeds. As aflatoxin is difficult to remove good practice is essential to prevent any mould growth and so prevent problems.

Not all oilseed crops are suitable for processing at small scale, the most common types that are suitable include groundnut, sunflower, coconut, sesame, mustard seed, oil palm and shea nuts. Typical oil contents of common raw materials are shown in Table 1.

Table 1 Common oils and their uses

|

|

. |

. |

|

Castor |

35-55 |

Paints, lubricants |

|

Cotton |

15-25 |

Cooking oil, soaps |

|

Linseed |

35-44 |

Paints |

|

Rape/mustard |

40-45 |

Cooking oil |

|

Sesame |

35-50 |

Cooking oil |

|

Sunflower |

25-40 |

Cooking oil |

|

|

. |

. |

|

Coconut |

35 (Fresh) |

Cooking oil, soaps |

|

Groundnuts |

38-50 |

Cooking oil, soaps |

|

Palm Kernel |

46-57 |

Cooking oil, cosmetics |

|

Shea nuts |

34-44 |

Cooking oil, soaps |

|

Mesocarp Palm fruit |

av. 56 |

Cooking oil, soap |

In many cases the crude extracted oil is not suitable for human consumption until it has been refined to remove undesirable free fatty acids that taste rancid, dark colours and waxes. Refining involves considerable extra equipment costs. The most suitable oils for small and medium scale extraction are those that need little or no refining eg. mustard, sesame, groundnut, sunflower, palm and palm kernel .

Methods of extraction

Five common methods are used to extract oil:

a) Water assisted. Here the finely ground oilseed is either boiled in water and the oil that floats to the surface is skimmed off or ground kernels are mixed with water and squeezed and mixed by hand to release the oil.

b) Manual pressing. Here oilseeds, usually pre-ground, are pressed in manual screw presses. A typical press is shown in diagram 1.

c) Expelling. An expeller consists of a motor driven screw turning in a perforated cage. The screw pushes the material against a small outlet, the "choke". Great pressure is exerted on the oilseed fed through the machine to extract the oil. Expelling is a continuous method unlike the previous two batch systems.

d) Ghanis. A ghani consists of a large pestle and mortar rotated either by animal power or by a motor. Seed is fed slowly into the mortar and the pressure exerted by the pestle breaks the cells and releases the oil. Ghani technology is mainly restricted to the Indian sub-continent.

e) Solvent extraction. Oils from seeds or the cake remaining from expelling is extracted with solvents and the oil is recovered after distilling off the solvent under vacuum.

Most small enterprises will find that small expellers are the best technology choice. Methods such as water extraction and manual pressing only produce small amounts of oil per day, the extraction efficiencies are low and labour requirements high. Solvent extraction while highly efficient involves very substantial capital cost and is only economic at large scale. There are also health and safety risk from using inflammable solvents.

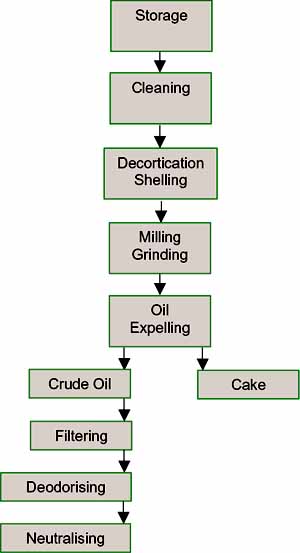

The basic steps involved in processing oilseeds by expeller are shown in the flow diagram below.

Equipment required

The equipment needed to set up a small or medium scale oil extraction enterprise falls into three main categories:

• pre-extraction equipment; eg dehullers, seed/kernel crackers, roasters, mills.

• extraction equipment; manual presses, ghanis, expellers

• equipment for basic refining of the oil; filters, settling tanks.

The specific equipment required will depend on the particular crop being processed, the final oil quality required and the scale of operation. In a small guide it is impossible to cover both the whole range of technical options and possible crops the following section concentrates on one example; the extraction of sunflower and groundnut oil by expeller.

Shelling or dehulling

Most oil bearing seed need to be separated from outer husk or shell. This is referred to as shelling, hulling or decortication. Shelling increases the oil extraction efficiency and reduces wear in the expeller as the husks are abrasive. In general some 10% of husk is added back prior to expelling as the fibre allows the machine to grip or bite on the material.

A wide range of manual and mechanical decorticators are available and typical examples are shown in Figure 2.

After decortication the shell may have to be separated from the kernels by winnowing. At small scale this can be done by throwing the material into the air and allowing the air to blow away the husk. At larger scale mechanical winnowers and seed cleaners are available

Heating or conditioning

Pre-heating the seeds prior to expelling speeds up the release of the oil. Pre-heating is generally carried out in a steam heated kettle mounted above the expeller.

Expelling

A wide range of makes and sizes of expellers are available. In India in particular a number of efficient small or "baby" expellers are available. A typical example with a capacity of up to 100 kg/hr is shown in figure.3. This machine has a central cylinder or cage fitted with eight separate sections or "worms". This flexible system allows single or double-reverse use and spreads wear more evenly along the screw. When the screw becomes worn only individual sections require repair thus reducing maintenance costs. As the material passes through the expeller the oil is squeezed out, exits through the perforated cage and is collected in a trough under the machine. The solid residue, oil cake, exits from the end of the expeller shaft where it is bagged.

Figure 4: Tinytech oil expeller in operation in Zimbabwe ©Practical Action/Keith Machell

Filtration

The crude expelled oil contains solid particles. These can be removed by allowing the oil to stand and then filtering the clear oil by gravity through fine cloth. A better but more expensive method is pumping the crude oil through a filter press.

The typical system described above can be obtained for about $US 4500 (1992 price) and consists of:

Decorticator with blower to remove shell, 150 kg/hr

Boiler, 50 kg steam/hr at 30 psi

Cooker

Expeller 75 -100 kg/hr

Filter pump and press.

If filling into retail packs is planned a simple manual piston filler would be required.

Production capacity

A small mill as described above has the following capacity (based on single shift, 8 hrs/day, 24 days/month)

|

. |

|

|

|

Groundnut Seed |

864 |

248,832 |

|

oil litres |

260 |

74,976 |

|

oilcake |

566 |

163,164 |

|

Sunflower Seed |

720 |

207,360 |

|

oil litres |

159 |

45,888 |

|

oilcake |

522 |

150,444 |

Economic viability will be greatly increased if the mill works double shift.

In terms of employment a small oil mill would provide work for the owner/manager and four workers.

Equipment suppliers

Note: This list of suppliers does not imply endorsement by Practical Action.

Chetan Agro industries

108, Atul Complex, Gondal Road, Opp: Bombay Hotel, RAJKOT - 360 002 INDIA . PHONE : +91-281-2461781 FAX +91-281-2461782 Web: [www.chetantent.com]

Agro Industrial Agency

Near Malaviya Vadi, Gondal Road, Rajkot - 360 002, India

Tel: +91 281 461134/462079/451214, Fax: +91 281 461770

• "Jagdish" Tiny Oil Press: Used for the extraction of vegetable oil from oilseeds. The reverse worm system in the pressing chamber results in the highest recovery of oil. Food Groups: Oilseeds. Capacity: 50 kg/hour, Power: Diesel/Electric

TinyTech Plants Tagore Road, Rajkot - 360 002, India

Tel: +91 281 2480166, 2468485, 2431086, Fax: +91 281 2467552

Website: http://www.tinytechindia.com/

• Oil expellers : Capacity: 125 kg/hour. Power: Electric

• Filter Press: This is suitable for the filtration of oil. It gives transparent, very clean oil without any solid particles. Food Groups: Oilseeds, Capacity: 100-200 litres/hour

Alvan Blanch Chelworth Malmesbury, Wiltshire, SN16 9SG, UK. Tel: +44 (0) 666 577333, Fax: +44 (0) 666 577339

• Expellers / Oil Screw Press - model mini 50: Barrel constructed from separate cast rings spaced apart by shims. The barrels are 60mm diameter by 155mm drainage length with a single piece worm shaft driven from the discharge end through a totally enclosed intermediate chain. The unit is complete with feed hopper, manual feed chute, oil discharge spout and base plate. A versatile, low cost machine, designed to suit village communities or small industries. Suitable for oil and cattle cake. Food Groups: Oilseeds, Capacity: 50 kg/hour input. Power: Diesel/Electric

C S Bell Co 170 West Davis Street, PO Box 291, Tiffin, Ohio, USA, Tel: +1 419 448 0791, Fax: +1 419 448 1203 • No.60 Power Grist Mill: This mill is suitable for use on large and small farms. Adjustable for grinding texture. Includes hopper, feed regulator slide, coarse and fine grinding burrs and 12 inch diameter pulley. Food Groups: Cereals/Oilseeds/Herbs/spices, Capacity: 150 kg/hour, Power: Electric/Manual

Forsberg Agritech India PVT Ltd 123, GIDC Estate, Makarpura, Baroda - 390 010 India. Tel: +91 (0) 265 645752, Fax: +91 (0) 265 641683.

• Pneumatic Aspirator / Winnower

This machine is used for "air washing" of the material to remove all dust, lights and impurities which are lighter than the seed. Winnowing of harvested and threshed seeds.

Food Groups: Cereals/Herbs/spices/Oilseeds

Ashoka Industries Kirama Walgammulla, Sri Lanka, Tel: +94 71 764725

• Oil Expeller: Food Groups: Oilseeds, Capacity: 5 litres/hour. Power: Electric.

Goldin India Equipment PVT Limited

F-29, B.I.D.C. Industrial, Estate, Gorwa, Vadodara - 390 016- Gujarat, India

Tel: +91 (0) 265 3801 168/380 461, Fax: +91 (0) 265 3801 168/380 461

• Screen Air Separator / Grain Cleaners:

Most suited as precleaner before storage of seeds. Variable speed drive ensures accurate quality separations at high capacity. Totally enclosed aspiration system with cyclone provides dust free working in the plant. Food Groups: Cereals/Herbs/spices/Oilseeds/Vegetables Capacity: 100 - 2000 kg/hour. Power: Battery/Electric

Flower Food Company

91/38 Ram Indra Road, Soi 10, Km 4, Bangkok, Thailand. Tel: +66 2 5212203 / 5523420

• Seed Decorticator Machine: Food Groups: Oilseeds, Capacity: 500 kg/hour. Power: Electric

Nigerian Oil Mills Ltd

P.O.Box 264, Atta, Owerri, Imo-State, Nigeria

• Milling Machine / Mills and Grinders

This machine is used for crushing palm kernels, groundnut seeds and moringa seeds to extract oil. Food Groups: Oilseeds/Nuts/Herbs/spices. Power: Electric/Manual

• Oil Expeller: This machine is used for crushing palm kernels, groundnut seeds and moringa seeds to extract oil. Food Groups: Oilseeds/Nuts/Herbs/spices. Power: Electric/Manual

Intermech Engineering Ltd P.O. Box 1278, Morogoro, Tanzania

.Oil Expeller: The machine expells oil from sunflower, sesame, neem, moringa, groundnuts, coconut, view details at http://www.intermech.biz

References and further reading

• The Manual Screw Press: For small-scale oil extraction Kathryn H. Potts and Keith Machell, ITDG Publications 1995

• Small Scale Vegetable Oil Extraction S.W. Head et al, NRI, ISBN 085954 387 0

This Howtopedia entry was derived from the Practical Action Technical Brief Small scale oil extraction.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_food_processing

Useful addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail:practicalaction@practicalaction.org.uk

web:www.practicalaction.org

Categories

- Medium

- Between 50 and 200 US$

- Up to 5 Persons

- Small Business

- Global Technology

- Agriculture

- Food Processing

- Products

- Oil

- Practical Action Update

- Requested translation to Spanish

- Requested translation to French

- Requested translation to Arabic

- Requested translation to Bangla

- Requested translation to Hindi

- Requested translation to Javanese

- Requested translation to Madarin

- Requested translation to Portuguese

- Requested translation to Russian

- Requested translation to Swahili

- Requested translation to Tamil