|

|

| Line 1: |

Line 1: |

| − | ==Short Description== | + | =Water Supplies for Food Processing - Technical Brief= |

| − | *'''Problem:''' Lack of Water

| |

| − | *'''Idea:''' Use Wind energy to pump water

| |

| − | *'''Difficulty:''' High

| |

| − | *'''Price Range:''' over 200 Dollars

| |

| − | *'''Material Needeed:'''

| |

| − | *'''Geographic Area:''' Global, where there is sufficient wind

| |

| − | *'''Competencies:'''

| |

| − | *'''How Many people?''' Up to 5

| |

| − | *'''How Long does it take?'''

| |

| | | | |

| − | =Windpumping - Technical Brief= | + | ==Introduction== |

| | | | |

| | <div class="booktext"> | | <div class="booktext"> |

| | | | |

| − | <center>'''PRACTICAL ACTION'''<br />'''Technology challenging poverty'''</center>

| + | Food and water are two of the relatively few items that people take into their bodies each day in order to stay alive (air and sometimes medicines being others). It is therefore essential, that food processors take the utmost care to prevent their products from becoming contaminated and causing illness or even the death of their customers. |

| | | | |

| − | </div>

| + | Foods are naturally contaminated with a wide range of bacteria, moulds and other organisms that can cause illness, but these are destroyed or prevented from growing during food processing when it is properly carried out. |

| | | | |

| − | ==Introduction==

| + | Three potential sources of contamination that can make properly processed foods unsafe are water supplies, unclean equipment and the operators in the production unit. This technical brief examines ways of ensuring that the risk of contamination from these sources is minimised. |

| | | | |

| − | <div class="booktext">

| + | Most countries have laws governing the hygienic requirements of food factories and food handlers. These should be checked during the planning stage of a food processing project. |

| | | | |

| − | Windpower technology dates back many centuries. There are historical claims that wind machines which harness the power of the wind date back to the time of the ancient Egyptians. Hero of Alexandria used a simple windmill to power an organ whilst the Babylonian emperor, Hammurabi, used windmills for an ambitious irrigation project as early as the 17th century BC. The Persians built windmills in the 7th century AD for milling and irrigation and rustic mills similar to these early vertical axis designs can still be found in the region today. In Europe the first windmills were seen much later, probably having been introduced by the English on their return from the crusades in the middle east or possibly transferred to Southern Europe by the Muslims after their conquest of the Iberian Peninsula. It was in Europe that much of the subsequent technical development took place. By the late part of the 13th century the typical 'European windmill' had been developed and this became the norm until further developments were introduced during the 18th century. At the end of the 19th century there were more than 30,000 windmills in Europe, used primarily for the milling of grain and water pumping. The first half of the 20th saw further development, particularly a move toward propeller type wind machines for electricity production.

| + | '''Water supplies''' |

| | | | |

| − | The major advances in the design of the windpump, however, took place in the USA. The technology was taken up and developed by the early pioneers or settlers who needed a method of lifting ground water for irrigation, for watering of livestock and later for providing water for steam locomotives which began to spread across the country. There were several significant technical developments to the commercial machines during this time; the ability of the machine to turn into the prevailing wind automatically; the development of a self governing mechanism which automatically turned the machine out of the wind when the wind velocity became high enough to cause damage; various improvements in rotor design and general durability and the introduction of gearing mechanisms. The technology was soon taken up worldwide, especially in the newly settled arid regions, such as South Africa, Australia and Argentina, where previously a lack of water had always prevented settlement and economic development in remote areas. By the 1920's 6 million windpumps were being used in the USA alone and their manufacture and use had become commonplace on every continent.

| + | Water is used for cleaning equipment, cooling containers and as a component of some foods. In each case only potable water should be used, it may therefore be necessary to treat water before it is used. There are two types of treatment: removal of suspended soils and removal/destruction of micro-organisms. |

| | | | |

| − | But the glory of the windpump was short-lived. With the advent of cheap fossil fuels in the 1950's and 1960's and the development of pumping technology the windpump became almost obsolete in the USA. Nowadays, with regular fuel crises and rising prices there has been a revival of interest in windpower but the windpump has yet to regain the status it held during its heyday.

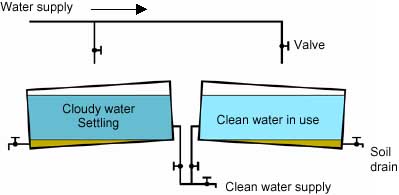

| + | Suspended soils can be removed by allowing them to settle out in settling tanks, see Figure 1 and/or filtering the water through specially designed water filters, see Figure 2. Both processes are relatively slow and large storage tanks are necessary if water is needed for washing or incorporation into the product. Water for cooling can be re-circulated. Although some types of water filters also remove micro-organisms, the easiest way of destroying them is to add chlorine solution (5-8ppm final concentration of chlorine obtained by diluting bleach to 0.02-0.04%). Lower chlorine levels (eg 0.5ppm) are needed if the water is to be used in a product to prevent 'off' flavours. Chlorination of water supplies can be simply arranged by allowing bleach to drip, at a fixed rate, into storage tanks or pipelines. The rate of bleach addition is found by experiment, using simple chlorine paper or more sophisticated probes to check the chlorine concentration. A less suitable alternative is to boil water to sterilise it. Water should be heated to boiling and then boiled vigorously for at least 10 minutes. This of course has a high fuel requirement and will therefore increase processing costs. |

| | | | |

| − | '''Windpumping for rural areas of the developing world'''

| + | <center> |

| | | | |

| − | There are manufacturers in several developing countries now producing windpumps. The uptake of wind machines for water pumping, however, has been generally very slow even though the technology is well suited to the demand of many regions of Africa, Asia and Latin America. Where they are used, the demand is for one of the following end uses:<br />

| + | [[Image:WaterSuppliesFoodProcessing01.jpeg]]<br /> Figure 1: Double settling tanks arrangement. Clean water is taken from one tank while impurities are left to settle in the other. |

| | | | |

| − | <blockquote> | + | </center><center> |

| | | | |

| − | • village water supplies<br /> • irrigation<br /> • livestock water supplies

| + | [[Image:WaterSuppliesforFoodProcessing02.gif]]<br /> Figure 2: Small-scale sand filter |

| | | | |

| − | </blockquote> | + | </center></div> |

| | | | |

| − | <br /> Water pumping is one of the most basic and widespread energy needs in rural areas of the world. It has been estimated that half the world's rural population does not have access to clean water supplies.

| + | ==Processing equipment== |

| − | | |

| − | </div>

| |

| − | | |

| − | ==Technical== | |

| | | | |

| | <div class="booktext"> | | <div class="booktext"> |

| | | | |

| − | '''The power in the wind'''

| + | The frequency and type of cleaning depends very much on the type of food being processed. Equipment for dry foods and powder does not require more than a simple brushing down each day whereas equipment that processes meat, milk and some vegetable products may need careful cleaning with both detergents and sterilants every few hours (because these foods can support the growth of potentially dangerous bacteria whereas dry foods cannot). |

| | | | |

| − | The wind systems that exist over the earth's surface are a result of variations in air pressure. These are in turn due to the variations in solar heating. Warm air rises and cooler air rushes in to take its place. Wind is merely the movement of air from one place to another. There are global wind patterns related to large scale solar heating of different regions of the earth's surface and seasonal variations in solar incidence. There are also localised wind patterns due the effects of temperature differences between land and seas, or mountains and valleys. | + | The type of cleaning depends on the nature of the soils on the equipment. In general, any equipment in which foods are deposited on the surfaces and then heated will be heavily soiled and difficult to clean. Table 1 shows examples of soils which are easy or hard to remove. |

| | | | |

| − | Windspeed data can be obtained from wind maps or from the meteorology office. Unfortunately the general availability and reliability of windspeed data is extremely poor in many regions of the world. However, significant areas of the world have mean windspeeds of above 3m/s which make the use of windpumps an economically attractive option. It is important to obtain accurate windspeed data for the site in mind before any decision can be made as to its suitability. Methods for assessing the mean windspeed are found in the relevant texts (see the 'References and resources' section at the end of this fact sheet).

| + | <div align="left"> |

| | | | |

| − | The power in the wind is proportional to:<br />

| + | {| border="1" cellpadding="5" |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | • the area of windmill being swept by the wind<br /> • the cube of the wind speed<br /> • the air density - which varies with altitude

| |

| − | | |

| − | </blockquote>

| |

| − | | |

| − | <br /> The formula used for calculating the power in the wind is shown below:<br />

| |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | P<sub>W</sub> = ½ ρ A V<sup>3</sup>

| |

| − | | |

| − | </blockquote><div align="left"><br />

| |

| − | | |

| − | {| cellpadding="5"

| |

| − | |- valign="top"

| |

| − | | valign="top" |

| |

| − | where,

| |

| − | | valign="top" |

| |

| − | P<sub>W</sub> is power in watts available in the wind (W)

| |

| − | |- valign="top"

| |

| − | | valign="top" |

| |

| − | ρ is the air density in kilograms per cubic metre (kg/m<sup>3</sup>)

| |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | A is the swept rotor area in square metres (m<sup>2</sup>)

| + | '''Soil''' |

| − | |- valign="top"

| |

| | | valign="top" | | | | valign="top" | |

| − | V is the wind speed in metres per second (m/s)

| + | '''Solubility in water''' |

| − | |}

| |

| − | | |

| − | </div>

| |

| − | | |

| − | The fact that the power is proportional to the cube of the wind speed is very significant. This can be demonstrated by pointing out that if the wind speed doubles then the power in the wind increases by a factor of eight! It is therefore worthwhile finding a site which has a relatively high mean wind speed.

| |

| − | | |

| − | '''Wind into watts''' | |

| − | | |

| − | Although the power equation above gives us the power in the wind, the actual power that we can extract from the wind is significantly less than this figure suggests. The actual power will depend on several factors, such as the type of machine and rotor used, the sophistication of blade design, friction losses, the losses in the pump or other equipment connected to the wind machine, and there are also physical limits to the amount of power which can be extracted realistically from the wind. It can been shown theoretically that any windmill can only possibly extract a maximum of 59.3% of the power from the wind (this is known as the Betz limit). In reality, for a windpump, this figure is usually around 30% to 40% and for a large electricity producing turbine around 45% maximum (see the section on coefficient of performance below)

| |

| − | | |

| − | So, modifying the formula for 'Power in the wind' we can say that the power that is produced by the wind machine can be given by:<br />

| |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | P<sub>M</sub> = ½.C<sub>p</sub> ρ A V<sup>3</sup>

| |

| − | | |

| − | </blockquote><div align="left"><br />

| |

| − | | |

| − | {| cellpadding="5"

| |

| − | |- valign="top"

| |

| | | valign="top" | | | | valign="top" | |

| − | where,

| + | '''Ease of removal''' |

| | | valign="top" | | | | valign="top" | |

| − | P<sub>M</sub> is power (in watts) available from the machine

| + | '''Typical foods''' |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | C<sub>p</sub> is the coefficient of performance of the wind machine

| + | Sugar |

| − | |}

| |

| − | | |

| − | </div>

| |

| − | | |

| − | It is also worth bearing in mind that a wind machine will only operate at maximum efficiency for a fraction of the time it is running, due to variations in wind speed. A rough estimate of the output from a windpump can be obtained using the following equation;<br />

| |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | P<sub>A</sub> = 0.1 A V<sup>3</sup>

| |

| − | | |

| − | </blockquote><div align="left"><br />

| |

| − | | |

| − | {| cellpadding="5"

| |

| − | |- valign="top"

| |

| | | valign="top" | | | | valign="top" | |

| − | where,

| + | Soluble |

| | | valign="top" | | | | valign="top" | |

| − | P<sub>A</sub> is the average power output in watts over the year

| + | Easy |

| − | |- valign="top"

| |

| | | valign="top" | | | | valign="top" | |

| − | V is the mean annual windspeed in m/s

| + | Preserves, fruit juices |

| − | |}

| |

| − | | |

| − | </div>

| |

| − | | |

| − | '''Principles of wind energy conversion'''

| |

| − | | |

| − | There are two primary physical principles by which energy can be extracted from the wind; these are through the creation of either lift or drag force (or through a combination of the two). The difference between drag and lift is illustrated by the difference between using a spinnaker sail, which fills like a parachute and pulls a sailing boat with the wind, and a Bermuda rig, the familiar triangular sail which deflects with wind and allows a sailing boat to travel across the wind or slightly into the wind.

| |

| − | | |

| − | Drag forces provide the most obvious means of propulsion, these being the forces felt by a person (or object) exposed to the wind. Lift forces are the most efficient means of propulsion but being more subtle than drag forces are not so well understood. The basic features that characterise lift and drag are:<br />

| |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | • drag is in the direction of air flow<br /> • lift is perpendicular to the direction of air flow<br /> • generation of lift always causes a certain amount of drag to be developed<br /> • with a good aerofoil, the lift produced can be more than thirty times greater than the drag<br /> • lift devices are generally more efficient than drag devices

| |

| − | | |

| − | </blockquote>

| |

| − | | |

| − | <br />'''Types and characteristics of rotors'''

| |

| − | | |

| − | There are two main families of windmachines: vertical axis machines and horizontal axis machines. These can in turn use either lift or drag forces to harness the wind. The horizontal axis lift device is the type most commonly used. In fact other than a few experimental machines virtually all windmills come under this category.

| |

| − | | |

| − | There are several technical parameters that are used to characterise windmill rotors. The ''tip-speed ratio'' is defined as the ratio of the speed of the extremities of a windmill rotor to the speed of the free wind. Drag devices always have tip-speed ratios less than one and hence turn slowly, whereas lift devices can have high tip-speed ratios (up to 13:1) and hence turn quickly relative to the wind.

| |

| − | | |

| − | The proportion of the power in the wind that the rotor can extract is termed the ''coefficient of performance'' (or power coefficient or efficiency; symbol C<sub>p</sub>) and its variation as a function of tip-speed ratio is commonly used to characterise different types of rotor. As mentioned earlier there is an upper limit of C<sub>p</sub> = 59.3%, although in practice real wind rotors have maximum C<sub>p</sub> values in the range of 25%-45%.

| |

| − | | |

| − | ''Solidity'' is usually defined as the percentage of the area of the rotor, which contains material rather than air (see Figures 1 & 2 below). High-solidity machines carry a lot of material and have coarse blade angles. They generate much higher starting torque (torque is the twisting or rotary force produced by the rotor) than low-solidity machines but are inherently less efficient than low-solidity machines. The windpump is generally of this type. Low-solidity machines tend to be used for electricity generation. High solidity machines will have a low tip-speed ratio and vice versa.

| |

| − | | |

| − | <center>

| |

| − | | |

| − | [[Image:Windpumping01.jpeg]]<br /> Figure 1: Low solidity rotor ©Practical Action

| |

| − | | |

| − | </center>

| |

| − | | |

| − | The choice of rotor is dictated largely by the characteristic of the load and hence of the end use. Some common rotor types and their characteristics are shown in Table 1 below.

| |

| − | | |

| − | <center>

| |

| − | | |

| − | [[Image:Windpumping02.jpeg]]<br /> Figure 2: High solidity rotor ©Practical Action

| |

| − | | |

| − | </center><div align="left">

| |

| − | | |

| − | {| border="1" cellpadding="5"

| |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | Type

| + | Fat |

| − | | valign="top" |

| |

| − | Speed

| |

| − | | valign="top" |

| |

| − | Torque

| |

| − | | valign="top" |

| |

| − | C<sub>p</sub>

| |

| | | valign="top" | | | | valign="top" | |

| − | Solidity (%)

| + | Insoluble |

| | | valign="top" | | | | valign="top" | |

| − | Use

| + | Difficult |

| − | |- valign="top"

| |

| | | valign="top" | | | | valign="top" | |

| − | '''Horizontal axis'''

| + | Meat, dairy products |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | Multi blade

| + | Protein |

| | | valign="top" | | | | valign="top" | |

| − | Low

| + | Insoluble |

| | | valign="top" | | | | valign="top" | |

| − | High

| + | Very difficult |

| | | valign="top" | | | | valign="top" | |

| − | 0.25 - 0.4

| + | Meat, dairy products |

| − | | valign="top" |

| |

| − | 50 - 80

| |

| − | | valign="top" |

| |

| − | Mechanical power

| |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | Three-bladed aerofoil

| + | Mineral |

| − | | valign="top" |

| |

| − | High

| |

| − | | valign="top" |

| |

| − | Low

| |

| − | | valign="top" |

| |

| − | up to 0.45

| |

| | | valign="top" | | | | valign="top" | |

| − | Less than 5

| + | Variable |

| | | valign="top" | | | | valign="top" | |

| − | Electricity production

| + | Easy to difficult |

| − | |- valign="top"

| |

| | | valign="top" | | | | valign="top" | |

| − | '''Vertical axis'''

| + | Milk |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | Panemone

| + | Salts |

| − | | valign="top" |

| |

| − | Low

| |

| − | | valign="top" |

| |

| − | Medium

| |

| − | | valign="top" |

| |

| − | less than 0.1

| |

| | | valign="top" | | | | valign="top" | |

| − | 50

| + | Most soluble in acids |

| | | valign="top" | | | | valign="top" | |

| − | Mechanical power

| + | Depending on solubility |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | Darrieus

| + | Starch |

| − | | valign="top" |

| |

| − | Moderate

| |

| | | valign="top" | | | | valign="top" | |

| − | Very low

| + | Soluble if not heated |

| | | valign="top" | | | | valign="top" | |

| − | 0.25 - 0.35

| + | Easy to difficult depending on heating |

| | | valign="top" | | | | valign="top" | |

| − | 10 - 20

| + | Vegetables |

| − | | valign="top" |

| |

| − | Electricity production

| |

| | |} | | |} |

| | | | |

| | </div> | | </div> |

| | | | |

| − | Table 1: Comparison of rotor types | + | Table 1: Soil removal |

| − | | |

| − | </div>

| |

| − | | |

| − | ==Water pumping==

| |

| − | | |

| − | <div class="booktext">

| |

| − | | |

| − | '''Matching rotor and pump'''

| |

| − | | |

| − | When installing a windpump it is important to match the characteristics of the pump and the wind machine. A good interaction between pump and rotor is essential. The most common type of pump used for water pumping (especially for borehole water pumping) in conjunction with a windmill is the reciprocating or piston pump. The piston pump tends to have a high torque requirement on starting because, when starting, the rotor has to provide enough torque to overcome the weight of the pump rods and water in the rising main - once the rotor is turning, the torque requirement decreases because of the momentum of the revolving rotor. The windspeed can then drop to about 2/3 of the start-up windspeed before the windpump will stop.

| |

| − | | |

| − | Other common pump types used for windpumping are the progressive cavity or 'Mono' pump and the centrifugal pump. Both have advantages in certain circumstances but both also tend to be expensive and less commonly used.

| |

| − | | |

| − | Figure 3. illustrates a typical example of a modern multi-bladed windpump. The high solidity means high starting and running torque and low running speed which is desirable for use with the piston pump.

| |

| − | | |

| − | It is obviously important to match the water pumping demand with the available wind and hence decide upon a suitable rotor size. To calculate the demand we need to know the following data:<br />

| |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | • The head to which the water is to be pumped - in metres<br /> • volume of water to be pumped per day - in metres cubed

| |

| − | | |

| − | </blockquote>

| |

| − | | |

| − | <br /> For water at sea level the approximate energy requirement can be calculated using the following equation:<br />

| |

| − | | |

| − | <blockquote>

| |

| − | | |

| − | E = 0.002725 x volume x head (in kilowatt-hours)

| |

| − | | |

| − | </blockquote>

| |

| − | | |

| − | <br /> Typically pumping heads can vary between a few metres and 100m (and occasionally more), whilst the volume of water required can vary from a few cubic metres a day for domestic use to a few hundred cubic metres for irrigation.

| |

| − | | |

| − | '''Anatomy of windpump'''

| |

| − | | |

| − | A borehole is by far the most common water source from which the windpump will draw water. A classic multiblade farm windpump has a piston pump pumping to an elevated storage tank. There are many other configurations possible, depending on the nature of the water source and the demand. These machines have rotor diameters of between 1.5 and 8 metres but seldom exceed 4 or 5 metres. The power is transmitted from the rotor to the pump rods via a gearing system or via a direct drive mechanism. The movement of the pump rods cause the pump to lift water to the tank. Water can then be fed into the distribution network from the tank. The function of the tail vane is to keep the rotor orientated into the wind. Most windpumps have a tail vane, which is designed, for automatic furling (turning the machine out of the wind) at high wind speeds to prevent damage.

| |

| − | | |

| − | <center>

| |

| − | | |

| − | [[Image:Windpumping03.jpeg]]<br /> Figure 3: The Kitjito Windpump. Used to pump ground water in the Bhel region of Turkana for the Nomadic Pastorlists ©Practical Action

| |

| − | | |

| − | </center>

| |

| − | | |

| − | '''Windpumping with electricity'''

| |

| − | | |

| − | Although the multiblade windpump is by far the most common windpump in use, it is not the only option available. Another option, especially where there is a requirement for the pump to be sited remote from the wind machine, is to use an aerogenerator to provide electricity for an electric pump. Although they tend to be more expensive, they do have the advantage that the electricity can be used for other applications when not pumping and also that the electricity can be stored in batteries for use when the windspeed is insufficient for direct electricity supply.

| |

| | | | |

| | </div> | | </div> |

| | | | |

| − | ==Other issues== | + | ==Detergents and sterilants== |

| | | | |

| | <div class="booktext"> | | <div class="booktext"> |

| | | | |

| − | '''Local manufacture'''

| + | Detergents help remove the types of soils shown in Table 1 and different types are available for different soils. They do not however, destroy bacteria or sterilise the equipment. Sterilants destroy bacteria but do not help remove soils. It is therefore important, for proper cleaning, that soils are first removed with a detergent and the surface of the equipment is then sterilised with a sterilant. |

| − | | |

| − | Windpumps are manufactured in small numbers in various countries throughout the world. There are manufacturers producing windpumps in Europe, Australia, South Africa and the USA for export, but there are also commercial enterprises in developing countries manufacturing windpumps. One such manufacturer, RIIC (the Rural Industries and Innovations Centre) is mentioned below.

| |

| − | | |

| − | There have been several projects over the last couple of decades with the aim of transferring windpump technology to manufacturers in the South, and there has been some success. One such success story is the Kijito windpump (See figure 3), manufactured in Kenya. This windpump was originally developed by the Intermediate Technology Development Group - ITDG (now known as Practical Action) based in the UK in conjunction with Bobs Harries Engineering Ltd. (BHEL), Kenya. BHEL have further developed the Kijito design and currently produce about 25 windpumps a year with a capacity to produce up to 50 machines.

| |

| | | | |

| | <div align="left"> | | <div align="left"> |

| Line 312: |

Line 120: |

| | |- valign="top" | | |- valign="top" |

| | | valign="top" | | | | valign="top" | |

| − | '''Ownership, usage, maintenance and environmental impact''' | + | '''Type of detergent''' |

| − | | + | | valign="top" | |

| − | '''User Perspective - Windpumps in Botswana''' | + | '''Action''' |

| − | | + | |- valign="top" |

| − | A survey was conducted in Botswana on owners/ users of windpumps''.'' The aim was to determine the ownership, procurement and installation, use, environmental impact and promotion of windpumps. The survey revealed that 54% of the windpumps were owned by households and 23% by farmers groups or syndicates. The rest (23%) were owned by the community. The majority of the windpumps (85%) were purchased and the rest were donated. Fifty-six per cent of the respondents purchased windpumps or raised the money from the banks to purchase them, whereas 18% utilised group contributions. Most of the respondents purchased the windpumps from RIIC, the local supplier. The installation of the windpumps was done by RIIC in 69% of the cases and by owners and foreign dealers in 23% and 8% respectively. Ninety-two per cent of the respondents were of the opinion that the installation was done satisfactorily. The operators had been trained by the supplier in 39% of the cases and the remainder had either taught themselves (31%) or been taught by the local technicians (8%).

| + | | valign="top" | |

| − | | + | Alkaline |

| − | All respondents revealed that windpumps were used for pumping water for livestock as well as for irrigation and domestic purposes. Ninety-two per cent of the respondents were of the opinion that the windpump had significantly improved their water supply. Eighty-four per cent thought that windpumps satisfied the water needs of the community. Thirty-one per cent depended on windpumps entirely for their water pumping, while 69% had other systems. The respondents perceived windpumps as a good technology mainly because they were cheaper to use. One of the problems associated with the use of windpumps was the high frequency of breakdowns. Forty-six per cent indicated that they broke down once a year, 31% twice a year and 23% more than three times a year. Major repairs were done by RIIC (54%), local technicians (8%) or a combination of the two (8%).

| + | | valign="top" | |

| − | | + | Prevents mineral salt build-ups, removes fat. |

| − | The study also investigated the perception of respondents of the environmental impact of the use of windpumps. The majority (85%) thought the windpumps improve the scenery, whereas 15% said they do not make a difference. No negative impacts were reported. It was also the view of 92% of the respondents that the noise form the windpumps is not a nuisance. The respondents thought that the adoption of the windpump technology was constrained by factors such as the lack of appropriate policies, lack of awareness of the technology, high costs of maintenance and inadequate wind regimes.

| + | |- valign="top" |

| | + | | valign="top" | |

| | + | Neutral |

| | + | | valign="top" | |

| | + | Used for surfaces that are damaged by other detergents. |

| | + | |- valign="top" |

| | + | | valign="top" | |

| | + | Acid |

| | + | | valign="top" | |

| | + | Removes mineral salt scale. |

| | + | |- valign="top" |

| | + | | valign="top" | |

| | + | Solvent |

| | + | | valign="top" | |

| | + | Removes fat. |

| | |} | | |} |

| | | | |

| | </div> | | </div> |

| | | | |

| − | Source: Mosimanyane et al 1995 (cited in Karekezi & Ranja 1997)

| + | Table 2: The types of detergent are shown in |

| − | | |

| − | </div>

| |

| − | | |

| − | ==References and resources==

| |

| | | | |

| − | '''This Howtopedia entry was derived from the Practical Action Technical Brief ''Windpumping''. <br />To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_energy'''<br />

| + | The effectiveness of all detergents is increased by brushing and warming to 40-50°C (very high temperatures might cause soils to burn onto equipment and should therefore be avoided). Fats require temperatures above 70°C for removal. In practice the choice of detergent may be limited and it is best to try a small quantity of what is available to make sure that:<br /> |

| − | <div class="booktext">

| |

| | | | |

| − | 1. P. Fraenkel, R. Barlow, F. Crick, A. Derrick and V. Bokalders: Windpumps - A guide for development workers. ITDG Publishing, 1993

| + | <blockquote> |

| − | | |

| − | 2. David, A. Spera: Wind Turbine Technology, fundamental concepts of wind turbine engineering. ASME Press, 1994

| |

| − | | |

| − | 3. E. W. Golding: The Generation of Electricity by Wind Power. Redwood Burn Limited, Trowbridge, 1976

| |

| − | | |

| − | 4. Hugh Piggot: Windpower Workshop, building your own wind turbine. Centre for Alternative Technology, 1997

| |

| − | | |

| − | 5. S. Karekezi and T. Ranja: Renewable Energy Technologies in Africa. AFREPREN / SEI, 1997

| |

| − | | |

| − | 6. C. Borg, and H. Oden: The Kijito Windpump - A Private Initiative in Kenyan Rural Water Supply, Master's Thesis, Chalmers University of Technology, Goteborg, 1995

| |

| − | | |

| − | 7. Paul T. Smulders and Jan de Jongh: Wind Pumping: Status, Prospects and Barriers, Article, Renewable Energy, Vol. 5 Part 1, pp. 587-594, 1994

| |

| − | | |

| − | </div> | |

| − | | |

| − | ==Manufacturers==

| |

| − | | |

| − | <div class="booktext">

| |

| − | | |

| − | Note: This is a selective list of suppliers and does not imply endorsement by Practical Action.

| |

| | | | |

| − | Neale Consulting Engineers Ltd., Highfield,<br /> Pilcot Hill, Dogmersfield, Hants. RG27 8SX,<br /> United Kingdom<br /> Tel: +44 (0)1252 629199<br /> Fax: +44 (0)1252 815625<br /> Website:<br /><u>http://www.tribology.co.uk/poldaw.htm</u>

| + | • it removes the soil<br /> • it does not corrode the equipment<br /> • it does not foam excessively<br /> • it does not leave a taint in foods used afterwards. |

| | | | |

| − | Manufacture the Poldaw 3.5m Windpump.<br /> Southern Cross Industries (Pty.) Ltd.,<br /> P.O. Box 627, Bloemfontein 9300,<br /> South Africa.<br /> Tel: +27 (0)51 4343861<br /> Fax: +27 (0)51 4343575<br /> Manufacture and supply windpumps.

| + | </blockquote></div> |

| | | | |

| − | The Rural Industries Innovations Centre,<br /> (Subsidiary of Rural Industries Promotions Company. Website: <u>http://www.ripco.co.bw</u>),<br /> P/Bag 11, Kanye, Botswana.<br /> Tel: +267 340392<br /> Fax: +267 340642

| + | =='''References and further reading'''== |

| | | | |

| − | Abachem Engineering Ltd., Jessop Way,<br /> Newark, Notts. NG24 2ER, UK.<br /> Tel: +44 (0)1636 676483<br /> Fax: +44 (0)1636 708632.<br /> Manufacture and supply windpump and 'submerged control leakage pump'.

| + | '''This Howtopedia entry was derived from the Practical Action Technical Brief ''Energy from the Wind''. <br />To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_water |

| | + | '''<br /> |

| | | | |

| − | Stewarts & Lloyds, 37 Leopold Takawira St.,<br /> Harare, P.O. Box 784, Zimbabwe.<br /> Tel: +263 4 708191<br /> Fax: + 263 4 790972<br /> Manufactures of the IT Windpump.

| + | =='''Usefull addresses'''== |

| − | | |

| − | Bobs Harries Engineering Ltd., P.O.Box 40,<br /> Thika, Kenya.<br /> Tel: +254 151 47234 or 47250<br /> Fax: +254 151 47233

| |

| − | | |

| − | '''Practical Action, The Schumacher Centre for Technology & Development'''<br />'''Bourton Hall, Bourton-on-Dunsmore, Rugby, Warwickshire CV23 9QZ, UK'''<br />'''Tel: +44 (0)1926 634400 Fax: +44 (0)1926 634401 E-mail: [mailto:Infoserv@practicalaction.org.uk Infoserv@practicalaction.org.uk] Web: http://www.practicalaction.org'''<br />'''Intermediate Technology Development Group Ltd Patron HRH -The Prince of Wales. KG, KT, GCB'''<br />'''Company Rag. No 871954, England Rag. Charity No 247257 VAT No 241 5154 92'''

| |

| − | | |

| − | </div>

| |

| − | =='''Useful addresses'''== | |

| | '''Practical Action''' | | '''Practical Action''' |

| | The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.<br /> | | The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.<br /> |

| Line 380: |

Line 171: |

| | =='''Categories:'''== | | =='''Categories:'''== |

| | [[category:Example]] | | [[category:Example]] |

| − | [[Category:Difficult]] | + | [[Category:Easy]] |

| − | [[Category:More than 200 US$]] | + | [[Category:Less than 10 US$]] |

| − | [[Category:Up to 5 Persons]] [[Category:Global Technology]] | + | [[Category:One Person]] |

| − | [[Category:Energy]] [[Category:Mechanics]] | + | [[Category:Global Technology]] |

| | + | [[Category:Water]] [[Category:Agriculture]] [[Category:Pest control]] [[Category:Soil]] [[Category:Food Processing]] [[Category:Health]] |