What to Do with Clay

THIS IS THE FULL TEXT COLLECTION OF ALL RELATED ARTICLES:

Contents

- 1 How to Make a Coffee-Clay Water Filter

- 2 How to Start Culture in Zai Holes

- 3 How to Use the Porous Clay Pots and Pipes System

- 4 Porous Clay Pots and Pipes for Small-scale Irrigation

- 4.1 Short Description

- 4.2 Technical Description

- 4.3 Clay pipes

- 4.4 Extent of Use

- 4.5 Advantages

- 4.6 Difficulty

- 4.7 The crops you can grow...

- 4.8 Clay pots / Pitcher and Salinity

- 4.9 The profitability of pitcher irrigation

- 4.10 Related articles

- 4.11 Links

- 4.12 Bibliography

- 4.13 Contact

- 4.14 Related Articles

- 4.15 Categories

- 5 How to Make a Desert Fridge

- 6 How to make a desert fridge or zeer pot

- 7 Clay as a Binder

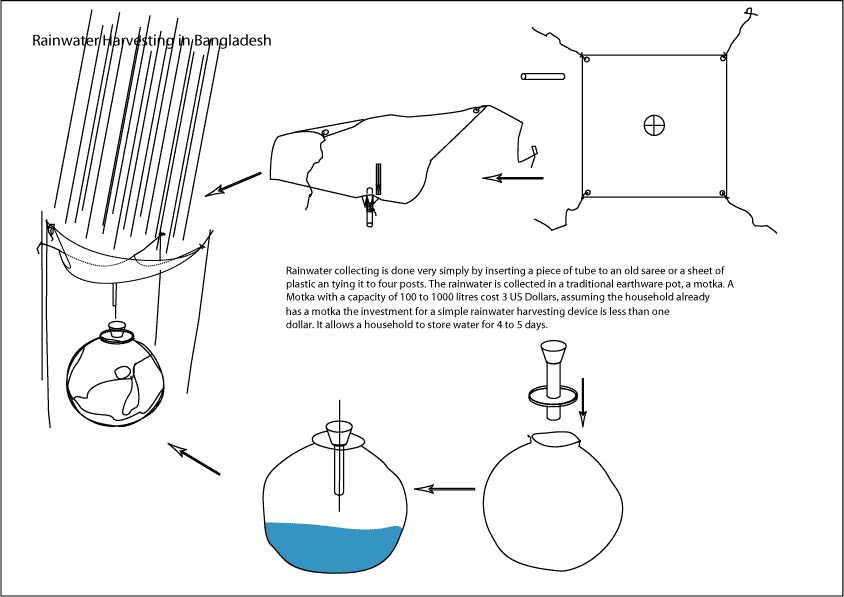

- 8 How to Harvest Water

How to Make a Coffee-Clay Water Filter

Water-borne, diarrhoea-causing bacteria, such as E. coli, kill 1.6 million people every year.

A cheap and simple water filter that Anyone can make Anywhere

Those filters are made from clay because it's easy to use and most importantly... it's free.

But fired clay alone is too dense to let the water pass at a desirable pace. Therefore some organic material is being added to increase the porousity: Organic material - like used coffee grounds, grounded rice husk, tea leaves or straw, papier-maché... - will would burn up in the firing process and leave tiny holes in the clay.

Clay and Grounded coffee are materials widely available around the world.

- Mix equal parts: One handful of clay, one handful of coffee grounds, for exemple from a collecting bin at the local coffee shop. Mix with enough water to form a thick biscuit like paste and form a cylindrical recipient with this paste. The walls of the filter should be as thick as an adult's index.

- Leave it in the sun to dry.

- fire the clay with cow manure: pack the pots in dry straw, and after you lay them on a first layer of dry cow dung, cover them with it completely.

A dung fire burns at around 950 degrees C - the right temperature for firing clay. The filters should turn bright orange during the firing process and stay so for 30 min.

It normally takes about an hour of baking in the dung to fire the filter.

The bacteria are slightly bigger than the pores of clay and get trapped in the clay. The coffee increases the porosity and the contact surface of the clay.

Lab tests showed that the clay and coffee combination works well:

it takes one to two hours to filter one litre of water, and the coffee-clay filter removes up to 99.8 percent of bacteria in water.

Contact

Mr. Tony Flynn

Department of Engineering,

Faculty of Engineering & Information Technology,

The Australian National University, Canberra ACT 0200

Telephone: +61 2 6125 0078 FAX: +61 2 6125 0506

Website: ClayPotFilter_final_web.pdf

http://info.anu.edu.au

Related Articles

- How to Filter Water with a Sand Filter

- How to Lower Water Turbidity with a Roughing Filter

- How to Pasteurize Water with a Plastic Bottle

- Water Supplies for Food Processing

- How to Purify Water with Moringa Seeds

- How to Purify Water With Solar Distillation

- How to Improve Water Quality Using Vetiver Grass

Categories

How to Start Culture in Zai Holes

Short Description

- Problem: Crusted land in arid regions, soil fertility, soil conservation, water conservation

- Idea: Planting crop in small holes enriched with compost

- Difficulty: Medium

- Price Range:

- Material Needeed: Digging material, Compost

- Geographic Area: Arid areas

- Competencies:

- How Many people?

- How Long does it take? Approx. 300 up to 450 hours per hectare digging the zai, 150 hours per hectare filling up with manure.

- Other Names: Planting pits, tassa

Description

Mali and Burkina Faso's Farmers apply the Zai technique to recover crusted land in semi-arid regions.

Zai is a hole, a planting pit with a diameter of 20-40 cm and a depth of 10-20 cm - the dimensions vary according to the type of soil. Pits are dug during the dry season from November until May and the number of Zai pits per hectare varies from 12,000 to 25,000.(The number of zai per hectare and their dimensions determine how much water they harvest. The bigger the number and the smaller their size, the less water they each harvest.)The excavated earth is ridged around the demi-circle to improve the water retention capacity of the pit.

After digging the pits, composted organic matter is added at an average, recommended rate of 0.6 kg/pit and, after the first rainfall, the matter is covered with a thin layer of soil and the seeds placed in the middle of the pit.

Zai fulfils three functions: soil and water conservation and erosion control for encrusted soils. The advantages of Zai are that it :

- captures rain and surface/ run-off water;

- protects seeds and organic matter against being washed away;

- concentrates nutrient and water availability at the beginning of the rainy season;

- increases yields; and

- Reactivates biological activities in the soil and eventually leads to an improvement in soil structure.

- The manure applied to the pits contains seeds of trees or bushes. This helps the regeneration of the vegetation on fields treated with pits.

The application of the Zai technique can reportedly increase production by up to 500% if properly executed.

Difficulties

- High labour to dig the zai holes ( between 300 and 450 hours/hectare)

- High maintenance labour (in soils with a high clay or gravel portion, pits require less maintenance than pits dug in sandier soils.)

- No mechanization possible.

- The pits should be dug during the dry season.

- Size and position are important.

- Composted organic material should be used, not raw organic material.

Success Story

Plans, Illustrations, Posters

Contacts

Links

http://www.ifpri.org/divs/eptd/dp/eptdp114.htm

http://www.worldbank.org/afr/ik/iknt80.htm

Bibliography

Related articles

- How to Use the Porous Clay Pots and Pipes System

- How to Start Composting

- How to Fight Soil Erosion by planting Vetiver Grass

Categories

How to Use the Porous Clay Pots and Pipes System

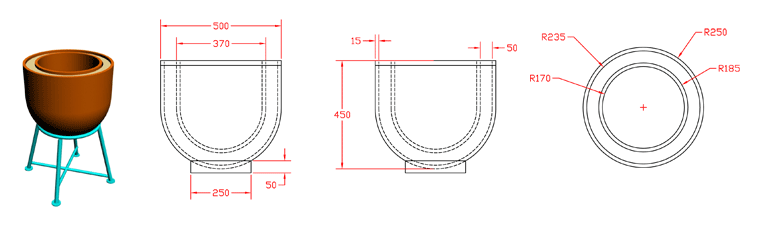

Porous Clay Pots and Pipes for Small-scale Irrigation

Short Description

- Problem:

- Idea:Porous clay pots and pipes conserve water and enable crops to grow in areas where they otherwise could not grow. With this technology, it becomes possible to save water and irrigate small vegetable gardens in rural areas.

- Difficulty:The initial labour required to manufacture the pots/pipes and install this technology is very high. The use of clay pots can be more labour intensive than traditional methods of watering crops, and may have difficulty in coping with providing adequate water for crops with high water requirements. Also, the porosity of pots decreases with time, and they have to be replaced at intervals. Pot lifespans are greatly reduced by the use of turbid water with a high silt and clay content. The silt accumulates in the pores, effectively sealing the pipes/pots.

- Price Range: Since this technology uses clay pots and clay pipes that are locally manufactured, the costs are normally low. The major cost is the cost of labour, which is estimated at approximately $40/ha in Zimbabwe.

- Material Needeed: locally available clay / unglazed clay pots

- Geographic Area:This technology is most suitable for dry areas with less than 500 mm rainfall/year.

- Competencies:Communal farmers, especially women, can manufacture the pots/pipes without having to develop special skills.

- How Many people?

- How Long does it take?

Technical Description

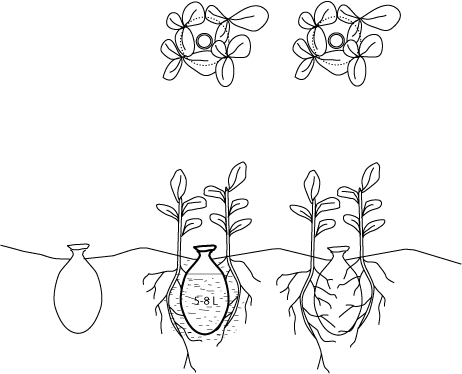

Pitcher Irrigation or Clay pots irrigation is an inexpensive small-scale irrigation method practiced in the semi-arid state of Karnal, India. The system consists of burying unglazed clay pots in the soil up to their neck. When the pot is filled with water, the natural pores in the pot's walls allow water to spread laterally in the soil, creating the moist conditions necessary for plant growth. Pitchers are filled as needed, maintaining a continuous supply of water directly to the plant root zone.

Pitcher irrigation is used for small-scale irrigation where:

- Water is either scarce or expensive.

- Fields are difficult to level such as under uneven terrain.

- Water is saline and cannot be normally used in surface methods of irrigation.

- In remote areas where vegetables are expensive and hard to come by.

One of the advantages of using pitchers for irrigation is the result of their water saving capacity.

To compare pitcher irrigation to flood or sprinkler irrigation one must correct for the fact that the scales are radically different. Pitcher irrigation is used on small-scale, while flood and sprinkler systems are for more extensive irrigation. Taking this into account, pitcher irrigation is still more efficient. Pitcher irrigation uses water more efficiently than other systems since it delivers water directly to plant root zones, instead of to broader areas of the field. With pitcher irrigation, deep percolation losses are negligible since water is released from smaller areas, and the rate of water loss can be controlled site to site by the amount of water put in each pitcher. Water requirements in a pitcher irrigated field can be even less than those of a drip irrigated system (of the same scale) due to the very low hydraulic conductivity of the pitchers, as well as reduced evaporation losses.

Clay pipes

Clay pipes irrigation is based on the same principle. Both clay pipes and clay pots can be homemade; most are installed by individual householders. The pipes are joined to form tubes of 250 mm in length with an inside diameter of 75 mm. The pipes are placed along the entire length of the beds by laying them end-to-end in a levelled trench. At one end, a right angle fitting is attached and an upright section of pipe installed. The trench is then backfilled with soil to a depth of 100 to 200 mm, depending upon the soil type. Water is poured into the porous pipe through the upright pipe. Each plant bed is about 3 to 6 m in length. The water seeps into the root zones through the joints between the individual pipes, or through the pipe walls if unglazed clay pipes are used. Alternatively, porous pots (made of unglazed clay) are buried in the soil up to their necks next to the plants or between plant rows at intervals of 300 mm. Water seeps from each pot through the pores and forms a wetted zone. Varying the frequency of filling, the size of the pots and the spacing between pots affects the watering process. Selection of the most suitable size of pot and its placement is governed by the type of crop.

Extent of Use

Adoption is fairly limited, possibly due to the fact that the initial stages are very labour-intensive. Trials in the dry areas of Chiredzi, Zimbabwe, have shown that communities are interested in this technology.

Once the systems are installed, there is very little maintenance required. Operation is quite simple.

Farmers, researchers and extension workers must work together to implement this technology. Communities can construct and operate the system. However, government officials and/or NGOs may have to work with pipe/pot manufacturers to ensure availability of supplies of suitable pots and pipes. Extension workers can assist farmers in pipe/pot placement for best effect and at depths/densities best suited for various types of crop.

Advantages

Material for clay pipes and pots, and local skills for pot-making, are readily available at negligible cost. This method provides a uniformly-wetted area, and, because water is applied at depth, often helps to reduce any weed problems - weeds generally have shallow root systems that are not well-served by this technology. Also, pots can be placed next to individual plants. Once the technology is installed the system can be used for several seasons. Effectiveness of the Technology It was found, during the replicated trials, that water savings varied from 11 to 28% of the water used with traditional irrigation.

Difficulty

The initial labour required to manufacture the pots/pipes and install this technology is very high. The use of clay pots can be more labour intensive than traditional methods of watering crops, and may have difficulty in coping with providing adequate water for crops with high water requirements. Also, the porosity of pots decreases with time, and they have to be replaced at intervals. Pot lifespans are greatly reduced by the use of turbid water with a high silt and clay content. The silt accumulates in the pores, effectively sealing the pipes/pots. Note: the turbidity and the salinity of the water can be reduced by the use of a sand filter. see How to Lower Water Turbidity with a Roughing Filter

- Price Range: Since this technology uses clay pots and clay pipes that are locally manufactured, the costs are normally low. The major cost is the cost of labour, which is estimated at

The crops you can grow...

There are a variety of crops that can benefit from pitcher irrigation practices. There currently is not a lot of information available on the internet on the differences in the techniques for each crop. There a few basic differences in technique.

As we have shown on our technical page, upright vegetable crops require a 7-10 liter clay pot and 3-6 plants can be grown surrounding each pot.

For creeping crops, or vines (i.e. melons, gourds, tomatoes...), the pot size can be 1-2 liters smaller and can be spaced further apart, requiring fewer pots per hectare.

Researchers at CSSRI found that the most profitable crops for pitcher irrigation in that area were (in order):

tomato> bottle-gourd> bitter-gourd> watermelon> cauliflower.

The muskmelon was unprofitable, thus they do not recommend its cultivation with pitcher irrigation.

Trees will require larger, deeper pots. Depending on tree spacing and species, one tree may require up to 3-4 pots.

Clay pots / Pitcher and Salinity

Research with pitcher irrigation at the Central Soil Salinity Research Institute (CSSRI) in Karnal India indicates that the amount of water which seeps out of the pots--and thus the number of plants which can be sustained by each pot--depends on the soil type, the porosity of the pot wall as well as the shape of the pot used. Pitchers are generally placed at distances so that wet areas do not overlap. Soil moisture and salt distribution in the plant rootzone are much more favorable with pitcher irrigation than with any surface method of irrigation. Under pitcher irrigation salt accumulates at the soil surface, leaving the salt content of water in the rootzone more favorable than the salinity of water used in the pitcher. Thus even saline water can be used for irrigation in the pitcher irrigation system. Watermelon and muskmelon both tolerated water salinity levels of up to 12 dSm-1. A tomato crop yielded almost 29 t/ha at 12 dSm-1 with 5000 pots/ha. Note that water of good quality for irrigation has a conductivity below 2 dSm-1, while sea water has a conductivity of about 46 dSm-1. Scientists at the Central Soil Salinity Research Institute have found that seven to ten litre pots are sufficient to grow most vegetable crops. The number of pitchers needed per hectare varies with the crop. At least four plants of most vegetable crops could be grown around one pot. A creeping crop such as bitter gourd required 2,000-2500 pitchers per hectare. Upright crops, or crops producing a canopy around the pot required more pots, up to 4,000-5000 pots per hectare.

The profitability of pitcher irrigation

The profitability of pitcher irrigation must consider the labor of acquiring, burying, and filling the pots, in addition to the labor involved in managing the crop.

The prospects of pitcher irrigation are reasonably high, especially in areas where water scarcity and salinity limit cultivation. The only difficulty with this method is the high labor demand which it places on the farmer. Pitcher irrigation may be an inappropriate solution where the labor needed to set up and run the system would fall on already overworked laborers.

Related articles

- How to Use the Porous Clay Pots and Pipes System

- How to Start Culture in Zai Holes

- Micro Irrigation

- How to Harvest Water

- How to Build an Underground Brick Dome Water Tank

- How to Build a Rainwater Tank: Sri Lankan Pumpkin Tank

- How to Recycle Organic Waste

- How to Harvest Rainwater

- How to Stock Water in Cement Water Jars

- Biomass and Liquid Biofuel (Technical Brief)

- How to Harvest Run Off Rainwater

- How to Fight Soil Erosion by planting Vetiver Grass

- How to Build the ARTI Compact Biogas Digestor

- How to Fight Soil Erosion

- How to Stop Gullies on Eroded Slopes

- How to Get a Hipporoller

- How to Make a Hand Pump

Links

http://www.unep.or.jp/ietc/publications/techpublications/TechPub-8a/clay.asp

Vegetables:

- Clay Pot and Porous Capsule Irrigation. http://www.oas.org/SP/PROG/chap5_7.htm

This site has detailed methods for steps involved in setting up a family vegetable garden.

- Bridging gaps in water and labour supply http://www.ileia.org/2/14-1/14-1-16.pdf

Discusses gardening applications in Africa. Also refers to other water-saving irrigation techniques for trees and creeping crops.

- Indigenous low input clay pot sub-irrigation for sustainable crop production http://www.info.bw/~saccar/clay.htm

A newsletter from the Southern African Center for Cooperation in Agricultural and Natural Resources Research and Training on pitcher irrigation implementation in Zambia. Includes methods and results of techniques and practice.

creeping plants and vines

- Pitcher Irrigation. http://fadr.msu.ru/rodale/agsieve/txt/vol2/8/art6.html

Gives background on irrigation used in semi-arid region of India. Discusses benefits of different types of creeping crops.

stalk crops and trees

- Irrigation and Surface Mulch to Improve Transplant Survival. http://www.serg.sdsu.edu/SERG/techniques/mulch.html

Discussion of experiment on deep pipe and clay pot irrigation.

Pitcher irrigation is a technique used in arid to semi-arid regions around the world. In addition to being less labor-intensive and more cost-effective, pitcher irrigation can also extend the growing season in many of these areas by efficiently providing water to crops throughout the dry season. Click on your area on the map below to find links to the articles specific to different regions

Africa

- CLAY POT SUB-SURFACE IRRIGATION AS WATER-SAVING TECHNOLOGY FOR SMALL-FARMER IRRIGATION

http://upetd.up.ac.za/thesis/available/etd-09062001-093813/unrestricted/08chapter7.pdf

Thesis chapter discussing small-farmer irrigation in sub-tropical Africa. Discusses all aspects including how to design pots from raw, local materials to field application. This is a large PDF file and may take some time to download.

- New FAO publication aims to bring small-scale irrigation to farmers in sub-Saharan Africa. http://www.fao.org/news/1997/970704-e.htm

- Pottery Irrigation on Peru's Arid Coast. http://www.idrc.ca/books/reports/V231/pottery.html

- Source Book of Alternative Technologies for Freshwater Augmentation in Latin America and the Carribean. http://www.oas.org/SP/PROG/srcecont.htm

Table of Contents page listing alternative irrigation techniques including pot and porous capsule irrigation.

South Asia/Middle East

- Pitcher Irrigation. http://fadr.msu.ru/rodale/agsieve/txt/vol2/8/art6.html

Gives background on irrigation used in semi-arid region of India. Discusses benefits of different types of creeping crops.

- Time-tested Pitcher Irrigation Helps Green the Slopes of Khanasser Valley http://www.icarda.cgiar.org/Publications/Caravan/caravan16/focus/time.htm

Implementation of pitcher irrigation in northern Syria.

- Communication between Dr. Basant Maheshawari and Thomas Stein. http://www.ibiblio.org/pub/academic/agriculture/agronomy/TRICKLE-L/199510xx.tri.html

Discusses pitcher irrigation implementation in India and gives general definitions and descriptions of irrigation techniques. We suggest doing a "Ctrl - F" search to find this particular dialouge on the site.

Bibliography

For more information and a copy of Pitcher Irrigation by R.C. Mondal, S.K. Gupta and S.K. Dubey, edited by H.K. Barthwal, Central Soil Salinity Research Institute, Karnal INDIA, Rakesh Press, 1987

See Volume 1 # 1 of the International Ag-Sieve for a brief description of pitcher irrigation in Uruguay.

Contact

Lowveld Research Station, Post Office Box 97, Chiredzi, Zimbabwe. Sourcebook of Alternative Technologies for Freshwater Augumentation in Africa

R.C. Mondal, Director Central Soil Salinity Research Institute Karnal-132001 INDIA

Related Articles

- How to Build Human-Powered Water-Lifters

- How to Build an Underground Brick Dome Water Tank

- How to Make a Hand Pump

- How to Make a Solar Pump

- How to Make a Hydraulic Ram Pump

- How to Build a Windpump (Principles)

- How to Use Diesel Engines

- How to Use Photovoltaic Energy

- How to Use Sun Power

- How to Use the Porous Clay Pots and Pipes System

- Micro Irrigation

Two ways to support the work of howtopedia for more practical articles on simple technologies:

Support us financially or,

Testimonials on how you use howtopedia are just as precious: So write us !

<paypal />

Categories

How to Make a Desert Fridge

How to make a desert fridge or zeer pot

Short Description

- Problem: Fruit and vegetable storage in hot climates

- Idea: Using the cooling power of evaporation. Two unglazed clay pots placed one in another and a wet sand layer in between.

- Difficulty: Easy

- Price Range: Local price of 2 unglazed clay pots

- Material Needed: 2 unglazed clay pots, sand, water, cloth or lid.

- Geographic Area: Hot and dry climates

- Competencies: None

- How Many people? 1

- How Long does it take? Wet the sand twice a day

Description

You can make a simple and effective cooling container for a dry climate with two clay pots, some sand, a cloth, and a little water. It works thanks the evaporation of water which cools down the inner pot.

One pot needs to fit inside the other with enough space between the two for a layer of sand (a few inches or a bit less than 10 cm thick). The cloth is large enough to cover the top of the largest pot.

Put a layer of sand in the bottom of the larger pot. Set the smaller pot on the sand and fill the gap between the two with more sand, right up to the top. Wet the sand. Put food in the inner pot. Cover the whole with the cloth or a lid.

Wet the sand about twice a day.

The zeer is the brainchild of teacher Mohammed Bah Abba. Bah Abba passed his idea to the Intermediate Technology Development Group (ITDG), which, with the assistance of researchers at the University of Al Fashir, carried out experiments to measure its value in maintaining nutrient content and extending the shelf life of vegetables.

On average, two zeers are used in homes, while women on the market will have three to four.

Zeer Pot. Drawing Khalifa Kamal

Benefits

- Each zeer can contain 12 kg of vegetables, and costs less than US$2 to produce.

- Experiments show that tomatoes and guavas can be kept for 20 days, compared to just two without.

- Eggplants stay fresh for 27 days.

- Even rocket, which usually lasts only a day before wilting, can be kept for five days.

- It is simple to use and to understand

- For the farmer, the zeer increases sales opportunities

- For the consumer the result is an increased supply of fresh vegetables and fruits in marketplace.

- Iman Mohamed Ibrahim of ITDG says women using the zeer to preserve their vegetables on the market can make an additional 25 to 30 per cent profit on their income.

- It can be used for storing sorghum and millets for a long time, as it protects from humidity when the sand is dry, preventing fungi from developing.

- The zeer can keep water at a temperature of about 15 degree Celsius.

- There is also a health benefit:the zeer helps maintain the vitamin and nutrient content of the vegetables, and prevent disease by keeping flies off the food.

Contacts

Women's Association for Earthenware Manufacturing in Darfur, with the support of ITDG, is producing and selling zeers for food preservation in the Al Fashir area

Links

See a longer discussion at: http://www.scienceinafrica.co.za/2004/september/refrigeration.htm

Categories

Clay as a Binder

Why use clay as a binder

The binding properties of clay are generally low compared with cement and, as already noted, reversible with water. Buildings of unstabilised earth face the risk of erosion unless special design precautions are taken to reduce exposure to rain and moisture.

On the other hand, stabilizers and other additives or methods such as good compaction and grain size optimization can reduce swelling, shrinkage, and cracking, increasing strength and water resistance, thus allowing economy in building.

When clay is mixed with water it becomes malleable, plastic or liquid, allowing it to be shaped. When drying, clay sets and recovers its cohesive properties, and so can bind the soil together.

Most soils consist of clay together with proportions of silt, sand and gravel. The larger particles give structure to a soil, while the clay holds it together and to a great extent provides the cohesion.

Earth is a ready building material and needs little further processing. Generally, a fairly wet mix with higher proportions of clay is used in moulding and spreading applications, while a mix with less clay is best suited to compaction in a moist or damp state.

Building design

For durability, earth should only be used where it is not prone to water or damp and, for maximum advantage, appropriate designs and construction techniques need to be selected. Optimum designs will depend a lot on the environment (natural drainage, water table...), the climate (rainfall, quantity and intensity, winds during rains...), and on the maintenance practices of the users, as well as on the sensitivity of the soil to water.

Figure 2: Private house built in the town of Amran in Yemen in 1985 ©CRATeere/EAG

Stabilization

To reduce or completely eliminate the reversibility of its cohesion and swelling properties earth can be stabilized using a diverse range of physico-chemical stabilizers.

Traditional stabilizers, which are usually obtained as or derived from naturally occurring substances, are mainly used with traditional building techniques. They are of three different types: glues (gum Arabic, animal glue...), oily products (sheanut butter, linseed oil...) and tannins (horse urine, decoction of néré tree bark...). The efficiency of these products is very variable, and often depends on local skills. Few have been scientifically studied even though many can be very efficient.

The main industrial stabilizers are cement, lime, and bitumen, and comprehensive information exists about these. Many other synthetic products have been tried but their performance is questionable, and doubts exist on their cost effectiveness.

Types of clay and soil

The proportions of the different components in a natural soil (clay, silts, sand, gravels and pebbles) are very variable. Ideally for building a soil should have a continuous grainsize distribution.

Another fundamental point is that the quality of the clay obtained can be very variable in composition and in characteristics.

The three principal types of clay are:

• Kaolinite, which is relatively stable and has relatively low cohesion;

• Illite, which is of average stability and cohesion, and;

• Montmorillonite, which is highly sensitive to water and has high cohesion.

A soil usually contains a combination of these clay types.

Although the properties of different soils vary widely, there are some characteristic soils (laterites, terra rossa, black cotton soils, loess, saline soils, and alluvial soils) the properties of which are relatively well known.

Suitability of soils

Some soils are suitable for use without any additives. Others can be improved (by addition of inert materials or by physico-chemical stabilisation of the clays). Finally, some have to be rejected (mostly soils with a high clay content or with montmorillonite clays).

There are some general requirements for the suitability of a soil for construction, but other requirements are specific to a particular construction application.

To get a good building material, strong and easy to use, the proportion of clay in a soil should be 15 per cent on average.

However, depending on cohesiveness of the clay relative to specific surface of the inert elements, generally 10 to 20 per cent clay content would be acceptable. The sand should be 40 to 80 per cent, the gravel 0 to 40 per cent and the silt 10 to 25 per cent.

If the clay content in a soil is too high, some minerals (sand, gravels…) or fibres (straw, hair…) can be added.

Identification of soils

Some simple field tests can be used to estimate the proportions of components in the soil to assess its suitability and to indicate how much stabilizer to use. They are also very useful for quality control.

Feeling the texture of the soil gives an indication of sand and gravel proportions as well as, when wet, its cohesiveness and strength. By letting the soil settle in water in a transparent container the sizes of the different layers indicates proportions of the components.

To estimate cohesion make a small biscuit or briquette of soil and observe if shrinkage is excessive after drying. After that, estimate its cohesiveness by the effort needed to break it. You can also roll a cigar (3cm in diameter) from a moistened and well-kneaded piece of soil and push it gently across the palm of the hand until a piece breaks off.

If the length of this piece is less than 5 cm, the soil contains too much sand, between 5 and 15 cm the soil is good, more than 15 cm and the soil contains too much clay.

Laboratory-based tests have also been developed and these are more accurate indicators.

Use of clays for mortars and plasters

An important application of earth for building, whether stabilized or not, is in mortars, plasters and renders. An essential requirement of these applications is that the materials used should not be significantly stronger than the backgrounds, otherwise the backgrounds can be damaged.

Plasters or renders are important in protecting walls from damage by rain, wind and abrasion, as well as for decorative effect, and earth-based materials are quite often used. Two further leaflets in this series describe these important applications of clays as building materials.

Figure 3: Church built in pisé (rammed earth) at Charancieu in the Dauphiné region of France ©CRATerre/EAG

Figure 4: The Kasbah of the Glaoui at Ouarzazate in Morocco. Built by the beginning of the 20th century ©CRATerre/EAG

References and further readings

Additives to Clay: Organic additives derived from Natural Sources, Practical Action Technical Brief

Additives to Clay: Minerals and synthetic additives, Practical Action Technical Brief

Mud Plasters and Renders: An Introduction Practical Action Technical Brief

Mud as a Mortar Practical Action Technical Brief

Earth construction, A comprehensive guide, CRATerre, ITDG Publishing, 1994.

Building with earth, CRATerre, Mud Village Society, Delhi, India, 1990.

Building with earth, A handbook, 2nd Ed., J. Norton, ITDG Publishing, 1997.

Soil preparation equipment (product information), GATE

Earth building materials and techniques, Select bibliography, CRATerre, GATE, 1991.

The basics of compressed earth blocks, CRATerre, GATE, 1991.

Appropriate building materials, A catalogue of potential solutions, 3rd Ed., R. Stulz, K. Mukerji, SKAT/ITDG Publishing, 1993

Earthen Architecture, Hands On Brief, ITDG/TVE, Series 1,

http://www.tve.org/ho/doc.cfm?aid=395&lang=English

Compressed Earth Blocks: Vol. 1, Manual of Production, Vince Rigassi, CRATerre-EAG, GATE/GTZ, 1985, http://www2.gtz.de/Basin/publications/books/CEBVol1.pdf

Useful contacts

CRATerre

Maison Levrat (Parc Fallavier)

B. P. 53, F-38092 Villefontaine -CEDEX

France

Tel: +33 474 954391

Fax: +33 474 956421

E-mail: craterre@club-internet.fr

Website: http://www.craterre.archi.fr

CRATerre is the international centre for earth construction at the school of Architecture in Grenoble. CRATerre is a member of basin.

Auroville Earth Institute

Auroshilpam, Auroville 605 101,

T.N. India

Tel: +91 413 262 3064/262 3330

Fax: +91 413 262 2886

Website: http://www.earth-auroville.com/

References and further reading

This Howtopedia entry was derived from the Practical Action Technical Brief Energy from the Wind.

To look at the original document follow this link: http://www.practicalaction.org/?id=technical_briefs_construction

Useful addresses

Practical Action

The Schumacher Centre for Technology & Development, Bourton on Dunsmore, RUGBY, CV23 9QZ, United Kingdom.

Tel.: +44 (0) 1926 634400, Fax: +44 (0) 1926 634401

e-mail: practicalaction@practicalaction.org.uk

web: www.practicalaction.org

Categories

How to Harvest Water

Related Articles

- How to Build an Underground Brick Dome Water Tank

- How to Build a Water Tank

- How to Purify Water with Chlorine Tablets

- How to Filter Water with a Sand Filter

- How to Lower Water Turbidity with a Roughing Filter

- Water Cleaning Principles

- How to Harvest Run Off Rainwater

- How to Harvest Rainwater

- How to Stock Water in Cement Water Jars

Categories

- Water

- Food Processing

- Health

- Hygiene

- Ideas

- Equipment Design

- Small Business

- Products

- Cooling

- Waste

- Sanitation

- Recycling

- Application

- Easy

- Less than 10 US$

- One Person

- Global Technology

- Rural Environment

- Urban Environment

- Montaneous Environment

- Forest Environment

- Temperate Climate

- Mediterranean Climate

- Tropical Climate

- Arid Climate

- Monsoon Climate

- Prevention

- Clay

- Coffee

- Sawdust

- Paper

- Stub

- Howtopedia requested images

- Howtopedia requested drawings

- Agriculture

- Community

- Composting

- Fertilizer

- Fruits

- Resource Management

- Soil

- Run-Off

- Tree

- Irrigation

- Biodiversity

- Water harvesting

- Easy to Medium

- Rainy season

- Charcoal

- Compost

- Cow dung

- Manure

- Seeds

- Seedlings

- Straw

- One Person and more

- Household

- Village

- Neighbourhood

- Requested translation to Spanish

- Crops

- Pumps

- Salt

- Vegetables

- Water purification

- Global

- Coastal Area

- Lakes and Rivers

- Banana

- Kaolin

- Requested translation to French

- Energy

- Cooking

- Medium

- Between 50 and 200 US$

- Between 2 and 5 People

- Construction

- Principles

- Ashes

- Fly Ash

- Coal

- Lime

- Cement

- Rice Husk

- Bricks

- Practical Action Update

- Concrete

- Pollution